Page 75 - Fundamentals of Magnetic Thermonuclear Reactor Design

P. 75

58 Fundamentals of Magnetic Thermonuclear Reactor Design

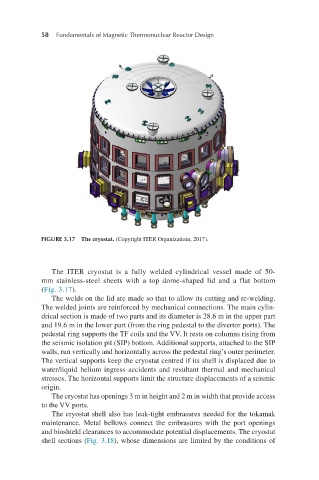

FIGURE 3.17 The cryostat. (Copyright ITER Organizatioin, 2017).

The ITER cryostat is a fully welded cylindrical vessel made of 50-

mm stainless-steel sheets with a top dome-shaped lid and a flat bottom

(Fig. 3.17).

The welds on the lid are made so that to allow its cutting and re-welding.

The welded joints are reinforced by mechanical connections. The main cylin-

drical section is made of two parts and its diameter is 28.6 m in the upper part

and 19.6 m in the lower part (from the ring pedestal to the divertor ports). The

pedestal ring supports the TF coils and the VV. It rests on columns rising from

the seismic isolation pit (SIP) bottom. Additional supports, attached to the SIP

walls, run vertically and horizontally across the pedestal ring’s outer perimeter.

The vertical supports keep the cryostat centred if its shell is displaced due to

water/liquid helium ingress accidents and resultant thermal and mechanical

stresses. The horizontal supports limit the structure displacements of a seismic

origin.

The cryostat has openings 3 m in height and 2 m in width that provide access

to the VV ports.

The cryostat shell also has leak-tight embrasures needed for the tokamak

maintenance. Metal bellows connect the embrasures with the port openings

and bioshield clearances to accommodate potential displacements. The cryostat

shell sections (Fig. 3.18), whose dimensions are limited by the conditions of