Page 77 - Fundamentals of Magnetic Thermonuclear Reactor Design

P. 77

60 Fundamentals of Magnetic Thermonuclear Reactor Design

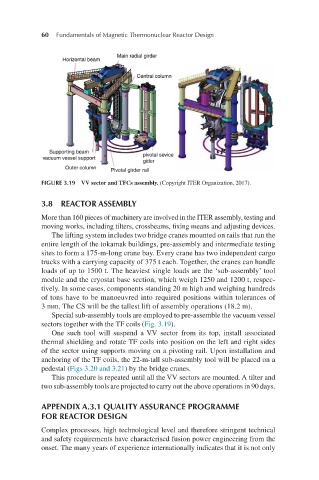

FIGURE 3.19 VV sector and TFCs assembly. (Copyright ITER Organization, 2017).

3.8 REACTOR ASSEMBLY

More than 160 pieces of machinery are involved in the ITER assembly, testing and

moving works, including tilters, crossbeams, fixing means and adjusting devices.

The lifting system includes two bridge cranes mounted on rails that run the

entire length of the tokamak buildings, pre-assembly and intermediate testing

sites to form a 175-m-long crane bay. Every crane has two independent cargo

trucks with a carrying capacity of 375 t each. Together, the cranes can handle

loads of up to 1500 t. The heaviest single loads are the ‘sub-assembly’ tool

module and the cryostat base section, which weigh 1250 and 1200 t, respec-

tively. In some cases, components standing 20 m high and weighing hundreds

of tons have to be manoeuvred into required positions within tolerances of

3 mm. The CS will be the tallest lift of assembly operations (18.2 m).

Special sub-assembly tools are employed to pre-assemble the vacuum vessel

sectors together with the TF coils (Fig. 3.19).

One such tool will suspend a VV sector from its top, install associated

thermal shielding and rotate TF coils into position on the left and right sides

of the sector using supports moving on a pivoting rail. Upon installation and

anchoring of the TF coils, the 22-m-tall sub-assembly tool will be placed on a

pedestal (Figs 3.20 and 3.21) by the bridge cranes.

This procedure is repeated until all the VV sectors are mounted. A tilter and

two sub-assembly tools are projected to carry out the above operations in 90 days.

APPENDIX A.3.1 QUALITY ASSURANCE PROGRAMME

FOR REACTOR DESIGN

Complex processes, high technological level and therefore stringent technical

and safety requirements have characterised fusion power engineering from the

onset. The many years of experience internationally indicates that it is not only