Page 441 - Fundamentals of Water Treatment Unit Processes : Physical, Chemical, and Biological

P. 441

396 Fundamentals of Water Treatment Unit Processes: Physical, Chemical, and Biological

sand in reductions of turbidity and coliforms, respectively,

BOX 13.1 ORGANIZING DILEMMA

for example, as seen in the plots, log R(turbidity) 0.8, log

Slow sand has a history: it is the first successful tech- R(coliforms) 2.

nology for municipal drinking water treatment. The

1829 London filter (Sections 13.1.4.1 and 13.1.4.2) 13.1.2.3 Economy

was the foundation for present practice. Its design by

The economic attractiveness of slow sand depends upon the

James Simpson was based on studies of filtration efforts

context. The appeal in current times is mostly for small

that were not successful and was refined by a pilot plant

communities. Communities having populations of 1000 to

study. Therefore, because of its history that fits the

2000 persons, or even 5000 persons, should not be too

themes of the book, for example, principles, modeling,

large for slow sand to be ‘‘appropriate.’’ At larger plants,

pilot plants, practice, and, the fact that it is one of the

however, the labor costs of processing sand (i.e., cleaning)

important technologies that is ‘‘on-the-shelf’’ for use,

will be greater than the cost of operation for rapid filtration.

and is appropriate for many situations, and perhaps

The point of this crossover will depend upon circumstances.

because of sentiments about slow sand, the decision The City of Salem, Oregon, however, with a population of

was to allocate a chapter to the topic. 107,000 (serving 135,000) uses slow sand filtration, as

does West Hartford, Connecticut with a population of

300,000 served; some others are listed by Slezak and

To assess the overall performance of a slow sand filter, Sims (1984). In Germany, slow sand is not uncommon and

London has 47 ha (116 ac) of slow sand filters. Slow sand

cartridge filter sampling is useful. Figure 13.2 shows cartridge

has been adopted in recent times in developing countries

filters after sampling the influent raw water and the filter

(van Dijk and Oomen, 1978; Kerkhoven, 1979; Komolrit

effluent, respectively, for the slow sand filter at Empire,

et al., 1979; Alagarsamy and Gandhirajan, 1981; Paramasivam

Colorado. The visual inspection gives an impression of the

et al., 1981; van Markenlaan, 1981), and in Puerto Rico (Gaya,

overall effectiveness of the filtration process. If the influent

1992).

cartridge filter is black in color after 100–200 L of water

throughput and the effluent cartridge remains white (or off-

white), then high removals may be expected of all organisms, 13.1.2.4 Labor

for example, algae, cysts, bacteria, viruses, etc. Heterotrophic Most of the labor is in scraping the sand bed, removing the

plate counts may be higher in the effluent, however, due to the sand from the box, washing, moving sand to and from storage,

growths within the biofilm. Also, while high turbidity and rebuilding the sand bed. The frequency of scraping has

removals are expected, this may not always be the case, for been about monthly at Empire, Colorado (population 450) and

example, for particles 1 mm (Bellamy, 1984; Bellamy et al., required about 30–60 min for two persons for one filter bed

2

2

1985a,b). having an area of 76.5 m or 825 ft (Seelaus et al., 1986,

To provide more quantitative assessment of slow sand p. 4). The sand was deposited on the ground outside the filter,

effectiveness, Figure 13.3 shows influent and effluent turbid- however, which deferred the labor of storing the sand for later

ities and influent and effluent coliforms in (a) and (b), respect- washing and resanding. The plant required a daily visit for

ively; the data were compiled by Sims and Slezak (1991) from flow adjustment, water level measurements, turbidity meas-

results of a national performance survey of slow sand filtration urements, and recording of data. By contrast, the Denver

3

plants. The plots are indicative of the quality of raw water Kassler plant (151,000 m =day or 40 mgd) employed

sources used for slow sand and of the effectiveness of slow 20 persons for continuous activity in scraping, washing,

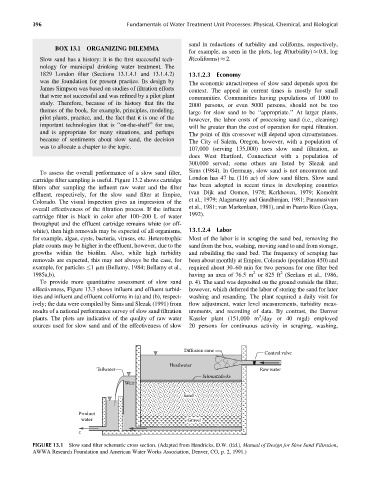

Diffusion cone

Control valve

Headwater

Tailwater Raw water

Schmutzdecke

Weir

Sand

Product

water Gravel

c

FIGURE 13.1 Slow sand filter schematic cross section. (Adapted from Hendricks, D.W. (Ed.), Manual of Design for Slow Sand Filtration,

AWWA Research Foundation and American Water Works Association, Denver, CO, p. 2, 1991.)