Page 486 - Fundamentals of Water Treatment Unit Processes : Physical, Chemical, and Biological

P. 486

Cake Filtration 441

Precoat circulation

Waste DE

Tank for septum

assembly storage

(6–12 months)

3–6 months storage

Pre-coat

tank P

Off-line

tank (being

backwashed)

Body-feed P

tank

P Raw water intake To disinfection

and storage

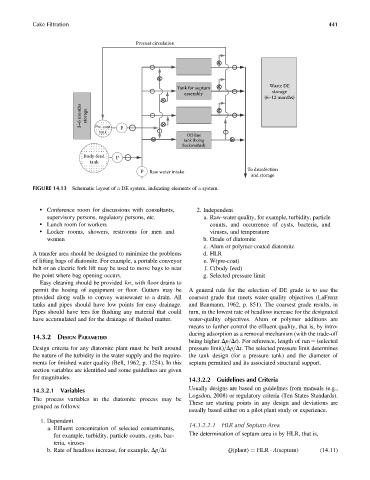

FIGURE 14.13 Schematic layout of a DE system, indicating elements of a system.

. Conference room for discussions with consultants, 2. Independent

supervisory persons, regulatory persons, etc. a. Raw-water quality, for example, turbidity, particle

. Lunch room for workers counts, and occurrence of cysts, bacteria, and

. Locker rooms, showers, restrooms for men and viruses, and temperature

women b. Grade of diatomite

c. Alum or polymer-coated diatomite

A transfer area should be designed to minimize the problems d. HLR

of lifting bags of diatomite. For example, a portable conveyor e. W(pre-coat)

belt or an electric fork lift may be used to move bags to near f. C(body feed)

the point where bag opening occurs. g. Selected pressure limit

Easy cleaning should be provided for, with floor drains to

permit the hosing of equipment or floor. Gutters may be A general rule for the selection of DE grade is to use the

provided along walls to convey wastewater to a drain. All coarsest grade that meets water-quality objectives (LaFrenz

tanks and pipes should have low points for easy drainage. and Baumann, 1962, p. 851). The coarsest grade results, in

Pipes should have tees for flushing any material that could turn, in the lowest rate of headloss increase for the designated

have accumulated and for the drainage of flushed matter. water-quality objectives. Alum or polymer additions are

means to further control the effluent quality, that is, by intro-

ducing adsorption as a removal mechanism (with the trade-off

14.3.2 DESIGN PARAMETERS

being higher Dp=Dt). For reference, length of run ¼ (selected

Design criteria for any diatomite plant must be built around pressure limit)=Dp=Dt. The selected pressure limit determines

the nature of the turbidity in the water supply and the require- the tank design (for a pressure tank) and the diameter of

ments for finished water quality (Bell, 1962, p. 1254). In this septum permitted and its associated structural support.

section variables are identified and some guidelines are given

for magnitudes.

14.3.2.2 Guidelines and Criteria

14.3.2.1 Variables Usually designs are based on guidelines from manuals (e.g.,

Logsdon, 2008) or regulatory criteria (Ten States Standards).

The process variables in the diatomite process may be

These are starting points in any design and deviations are

grouped as follows:

usually based either on a pilot plant study or experience.

1. Dependent 14.3.2.2.1 HLR and Septum Area

a. Effluent concentration of selected contaminants,

for example, turbidity, particle counts, cysts, bac- The determination of septum area is by HLR, that is,

teria, viruses

b. Rate of headloss increase, for example, Dp=Dt Q(plant) ¼ HLR A(septum) (14:11)