Page 482 - Fundamentals of Water Treatment Unit Processes : Physical, Chemical, and Biological

P. 482

Cake Filtration 437

500

70

Filter-Cel

C-512

400 60

50

Pressure loss (kPa) 300 Nominal Pressure limit 40 Pressure loss (psi)

Hyflo

30

200

100 C-535 20

C-545 10

0 0

0 50 100 150 200 250

Time (h)

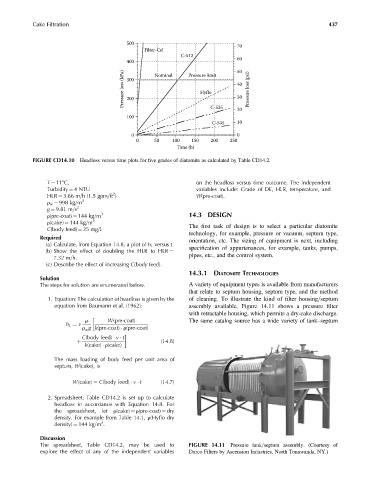

FIGURE CD14.10 Headloss versus time plots for five grades of diatomite as calculated by Table CD14.2.

T ¼ 118C, on the headloss versus time outcome. The independent

Turbidity ¼ 4 NTU variables include: Grade of DE, HLR, temperature, and

2

HLR ¼ 3.66 m=h (1.5 gpm=ft ) W(pre-coat).

r w ¼ 998 kg=m 3

g ¼ 9.81 m=s 2

r(pre-coat) ¼ 144 kg=m 3 14.3 DESIGN

r(cake) ¼ 144 kg=m 3

C(body feed) ¼ 25 mg=L The first task of design is to select a particular diatomite

technology, for example, pressure or vacuum, septum type,

Required orientation, etc. The sizing of equipment is next, including

(a) Calculate, from Equation 14.8, a plot of h L versus t.

specification of appurtenances, for example, tanks, pumps,

(b) Show the effect of doubling the HLR to HLR ¼

pipes, etc., and the control system.

7.32 m=h.

(c) Describe the effect of increasing C(body feed).

14.3.1 DIATOMITE TECHNOLOGIES

Solution

The steps for solution are enumerated below. A variety of equipment types is available from manufacturers

that relate to septum housing, septum type, and the method

1. Equation: The calculation of headloss is given by the of cleaning. To illustrate the kind of filter housing=septum

equation from Baumann et al. (1962): assembly available, Figure 14.11 shows a pressure filter

with retractable housing, which permits a dry-cake discharge.

m W(pre-coat) The same catalog source has a wide variety of tank–septum

h L ¼ v

r g k(pre-coat) r(pre-coat)

w

C(body feed) v t

(14:8)

þ

k(cake) r(cake)

The mass loading of body feed per unit area of

septum, W(cake), is

W(cake) ¼ C(body feed) v t (14:7)

2. Spreadsheet: Table CD14.2 is set up to calculate

headloss in accordance with Equation 14.8. For

the spreadsheet, let r(cake) ¼ r(pre-coat) ¼ dry

density. For example from Table 14.1, r(Hyflo dry

3

density) ¼ 144 kg=m .

Discussion

The spreadsheet, Table CD14.2, may be used to FIGURE 14.11 Pressure tank=septum assembly. (Courtesy of

explore the effect of any of the independent variables Durco Filters by Ascension Industries, North Tonawanda, NY.)