Page 483 - Fundamentals of Water Treatment Unit Processes : Physical, Chemical, and Biological

P. 483

438 Fundamentals of Water Treatment Unit Processes: Physical, Chemical, and Biological

assemblies, for example, wet-cake discharge, vertical oriented atmosphere and the pump is on the effluent side of the filters,

tank-vertical septum leaves, vertical tank-horizontal leaves, as creating a negative pressure within the septum.

well as different kinds of septum materials and construction.

14.3.1.1.3 Septum

The sizes of single tanks may be in the range of 914 d(tank)

1829 mm (36–72 in.) with 6 N(leaves) 34 (Durco Filters

The most common septum shape is the vertical leaf. As seen

by Ascension Industries, 2009). A system may be purchased

in Figure 14.11, the vertical leaf filter is a disk with septum on

as a ‘‘package’’ from a manufacturer or the tank–septum

both sides with vertical orientation. To permit the buildup of

system is purchased with components designed and obtained

cake and to provide for the uniform circulation of diatomite

separately. For smaller systems, a skid-mounted ‘‘package’’

slurry, without cake erosion, the discs should be spaced suf-

system may be more practical and for larger systems, individ-

ficiently far apart.

ual design may be more appropriate.

The septa have been made of a variety of materials, for

example, stainless steel wire cloth, synthetic fabrics, and

14.3.1.1 Equipment porous stone. The stainless steel wire cloth fits most of the

As noted previously, a variety of septum shapes have been criteria for a suitable septum material. Required openings in

provided by manufacturers along with different kinds of tanks one direction are 0.13 mm (0.005 in.) (Bell, 1962, p. 1245).

and approaches to septum cleaning. A system design always A sieve size of U.S. Standard 60, however, has an opening of

involves 2 tanks, each with its own set of components. In 0.25 mm (a Tyler 60 sieve has the same opening), which was

other words, the system design is modular, that is, the same used at Vacaville. Generally, the septum openings are larger

design is repeated for each tank. This means also that there is than the coarsest grades of DE. Bridging over the openings

no theoretical limit to the size of an installation. occurs as the pre-coat is circulated; once the bridging starts,

the pre-coat is formed.

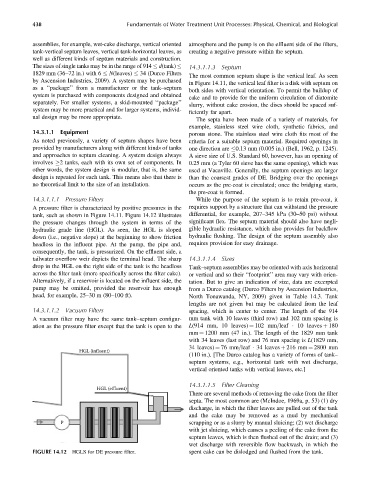

14.3.1.1.1 Pressure Filters While the purpose of the septum is to retain pre-coat, it

A pressure filter is characterized by positive pressures in the requires support by a structure that can withstand the pressure

tank, such as shown in Figure 14.11. Figure 14.12 illustrates differential, for example, 207–345 kPa (30–50 psi) without

the pressure changes through the system in terms of the significant flex. The septum material should also have negli-

hydraulic grade line (HGL). As seen, the HGL is sloped gible hydraulic resistance, which also provides for backflow

down (i.e., negative slope) at the beginning to show friction hydraulic flushing. The design of the septum assembly also

headloss in the influent pipe. At the pump, the pipe and, requires provision for easy drainage.

consequently, the tank, is pressurized. On the effluent side, a

tailwater overflow weir depicts the terminal head. The sharp 14.3.1.1.4 Sizes

drop in the HGL on the right side of the tank is the headloss Tank–septum assemblies may be oriented with axis horizontal

across the filter tank (more specifically across the filter cake). or vertical and so their ‘‘footprint’’ area may vary with orien-

Alternatively, if a reservoir is located on the influent side, the tation. But to give an indication of size, data are excerpted

pump may be omitted, provided the reservoir has enough from a Durco catalog (Durco Filters by Ascension Industries,

head, for example, 25–30 m (80–100 ft). North Tonawanda, NY, 2009) given in Table 14.3. Tank

lengths are not given but may be calculated from the leaf

14.3.1.1.2 Vacuum Filters spacing, which is center to center. The length of the 914

A vacuum filter may have the same tank–septum configur- mm tank with 10 leaves (third row) and 102 mm spacing is

ation as the pressure filter except that the tank is open to the L(914 mm, 10 leaves) ¼ 102 mm=leaf 10 leaves þ 180

mm ¼ 1200 mm (47 in.). The length of the 1829 mm tank

with 34 leaves (last row) and 76 mm spacing is L(1829 mm,

34 leaves) ¼ 76 mm=leaf 34 leaves þ 216 mm ¼ 2800 mm

HGL (influent)

(110 in.). [The Durco catalog has a variety of forms of tank–

septum systems, e.g., horizontal tank with wet discharge,

vertical oriented tanks with vertical leaves, etc.]

14.3.1.1.5 Filter Cleaning

HGL (effluent)

There are several methods of removing the cake from the filter

septa. The most common are (McIndoe, 1969a, p. 53) (1) dry

discharge, in which the filter leaves are pulled out of the tank

and the cake may be removed as a mud by mechanical

P scrapping or as a slurry by manual sluicing; (2) wet discharge

with jet sluicing, which causes a peeling of the cake from the

septum leaves, which is then flushed out of the drain; and (3)

wet discharge with reversible flow backwash, in which the

FIGURE 14.12 HGLS for DE pressure filter. spent cake can be dislodged and flushed from the tank.