Page 767 - Fundamentals of Water Treatment Unit Processes : Physical, Chemical, and Biological

P. 767

722 Fundamentals of Water Treatment Unit Processes: Physical, Chemical, and Biological

1. Diffused-air aeration or activated-sludge process

TABLE 23.1 proper. In this method of treatment, air is blown

Sampling of Biological Reactors into sewage as it flows through tanks, activated

sludge being added to the incoming sewage and

Suspended Growth Attached Growth

Reactors Reactors Reaction Type settled out in sedimentation basins from the tank

effluent. A part of the sludge produced is fed into

Activated sludge

the influent as ‘‘return sludge,’’ and a part is disposed

Conventional Trickling filters Aerobic

of as ‘‘excess sludge.’’

Plug-flow Bio-filters Anoxic

2. Mechanical aeration or bio-aeration. Mechanical

Complete-mix Rotating biological Nitrification

apparatus is employed in this method, to aerate the

contactors

sewage and keep the tank contents in circulation.

Extended aeration Soil, gravel Anaerobic

Absorption of air takes place from the atmosphere

Tapered aeration Granular activated Sludge

at the surface of the sewage.

carbon digesters

Hatfield process Anaerobic

reactors Metcalf and Eddy go on to describe three distinct functions of

Pasveer oxidation diffused air: (1) to provide oxygen necessary to attain aerobic

ditch conditions and promote the growth of oxidizing organisms,

chiefly bacteria; (2) to cause the activated sludge to move

Hydraulic

through the sewage and provide contact between the gelatin-

Ponds Hybrid Reactors Classification

ous surfaces of the sludge and the organic matter contained

Aerobic Imhoff tanks Continuous-flow

in the sewage; and (3) to prevent deposition of the sludge.

Anaerobic Septic tanks Plug-flow

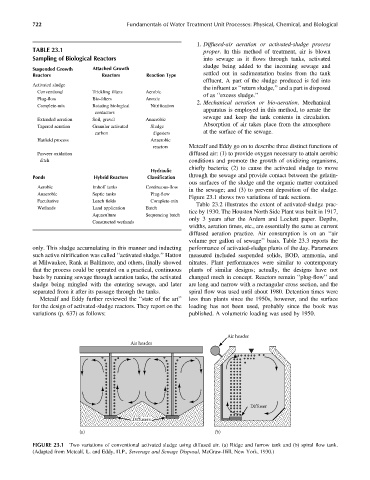

Figure 23.1 shows two variations of tank sections.

Facultative Leach fields Complete-mix

Table 23.2 illustrates the extent of activated-sludge prac-

Wetlands Land application Batch

tice by 1930. The Houston North Side Plant was built in 1917,

Aquaculture Sequencing batch

only 3 years after the Ardern and Lockett paper. Depths,

Constructed wetlands

widths, aeration times, etc., are essentially the same as current

diffused aeration practice. Air consumption is on an ‘‘air

volume per gallon of sewage’’ basis. Table 23.3 reports the

only. This sludge accumulating in this manner and inducting performance of activated-sludge plants of the day. Parameters

such active nitrification was called ‘‘activated sludge.’’ Hatton measured included suspended solids, BOD, ammonia, and

at Milwaukee, Rank at Baltimore, and others, finally showed nitrates. Plant performances were similar to contemporary

that the process could be operated on a practical, continuous plants of similar designs; actually, the designs have not

basis by running sewage through aeration tanks, the activated changed much in concept. Reactors remain ‘‘plug-flow’’ and

sludge being mingled with the entering sewage, and later are long and narrow with a rectangular cross section, and the

separated from it after its passage through the tanks. spiral flow was used until about 1980. Detention times were

Metcalf and Eddy further reviewed the ‘‘state of the art’’ less than plants since the 1950s, however, and the surface

for the design of activated-sludge reactors. They report on the loading has not been used, probably since the book was

variations (p. 637) as follows: published. A volumetric loading was used by 1950.

Air header

Air header

Diffuser

Diffusers

(a) (b)

FIGURE 23.1 Two variations of conventional activated sludge using diffused air. (a) Ridge and furrow tank and (b) spiral flow tank.

(Adapted from Metcalf, L. and Eddy, H.P., Sewerage and Sewage Disposal, McGraw-Hill, New York, 1930.)