Page 783 - Fundamentals of Water Treatment Unit Processes : Physical, Chemical, and Biological

P. 783

738 Fundamentals of Water Treatment Unit Processes: Physical, Chemical, and Biological

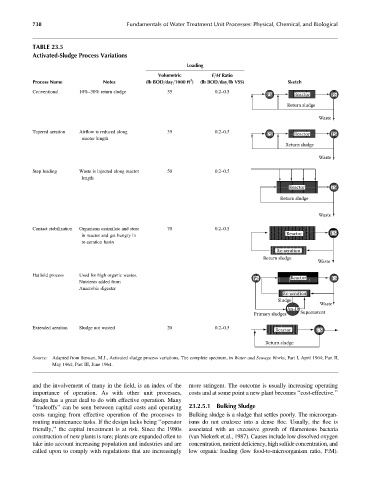

TABLE 23.5

Activated-Sludge Process Variations

Loading

Volumetric F=M Ratio

3

Process Name Notes (lb BOD=day=1000 ft ) (lb BOD=day=lb VSS) Sketch

Conventional 10%–30% return sludge 35 0.2–0.5

PS Reactor FS

Return sludge

Waste

Tapered aeration Airflow is reduced along 35 0.2–0.5

PS Reactor FS

reactor length

Return sludge

Waste

Step loading Waste is injected along reactor 50 0.2–0.5

length

Reactor FS

Return sludge

Waste

Contact stabilization Organisms assimilate and store 70 0.2–0.5

Reactor FS

in reactor and get hungry in

re-aeration basin

Re-aeration

Return sludge

Waste

Hatfield process Used for high organic wastes.

PS Reactor FS

Nutrients added from

Anaerobic digester

Re-aeration

Sludge

Waste

An-D

Primary sludges Supernatent

Extended aeration Sludge not wasted 20 0.2–0.5

Reactor FS

Return sludge

Source: Adapted from Stewart, M.J., Activated sludge process variations, The complete spectrum, in Water and Sewage Works, Part I, April 1964; Part II,

May 1964; Part III, June 1964.

and the involvement of many in the field, is an index of the more stringent. The outcome is usually increasing operating

importance of operation. As with other unit processes, costs and at some point a new plant becomes ‘‘cost-effective.’’

design has a great deal to do with effective operation. Many

‘‘tradeoffs’’ can be seen between capital costs and operating 23.2.5.1 Bulking Sludge

costs ranging from effective operation of the processes to Bulking sludge is a sludge that settles poorly. The microorgan-

routing maintenance tasks. If the design lacks being ‘‘operator isms do not coalesce into a dense floc.Usually,the floc is

friendly,’’ the capital investment is at risk. Since the 1980s associated with an excessive growth of filamentous bacteria

construction of new plants is rare; plants are expanded often to (van Niekerk et al., 1987). Causes include low dissolved oxygen

take into account increasing population and industries and are concentration, nutrient deficiency, high sulfide concentration, and

called upon to comply with regulations that are increasingly low organic loading (low food-to-microorganism ratio, F:M).