Page 856 - Fundamentals of Water Treatment Unit Processes : Physical, Chemical, and Biological

P. 856

Appendix D: Fluid Mechanics—Reviews of Selected Topics 811

TABLE D.7 TABLE D.8

Meter Coefficients for Flow Measurement Weir Coefficients for Flow Measurement

Meter Type Metering Formula d=D C D Meter Type Metering Formula H=P C w

0.5

Orifice Q ¼ C D A (2gDH) 0.5 0.10 0.60 Rectangular weir Q ¼ C w A (2g) w DH 0.5 0.00 0.40

0.20 0.60 0.10 0.405

0.30 0.60 0.20 0.41

0.40 0.62 0.30 0.415

0.50 0.63 0.40 0.42

0.60 0.65 0.50 0.43

0.70 0.70 0.60 0.43

0.80 0.77 0.80 0.44

Venturi Q ¼ C D A(throat) [2gDH] 0.5 0.50 1.00

Meter Type Metering Formula CV H

0.60 1.04 u

0.5

V-notch weir Q ¼ (8=15)C VH [2g] H 2.5 608 0.58

Notes: (1) D is diameter of pipe and d is diameter of orifice or Venturi Metric Q ¼ 0.79H 2.5 608 (H in m)

5 5

throat. (2) Coefficients are for R 10 ; for most flows, R 10 can U.S. Customary Q ¼ 1.44H 2.5 608 (H in ft)

5

be assumed. (3) For R < 10 can, the coefficient increases for orifices

3

3

and decreases for Venturi meters. Terms Q, flow in m =s (ft =s); C w , weir coefficient; g, acceleration of gravity

2

(9.81 m=s ).

Notes: (1) For a rectangular weir, C w ¼ 0.40 þ 0.05H=P. (2) For a V-notch

weir, C VN ¼ 0.58 when u ¼ 608. (3) General formulae work for SI

the pressure differential between upstream and downstream or U.S. Customary units.

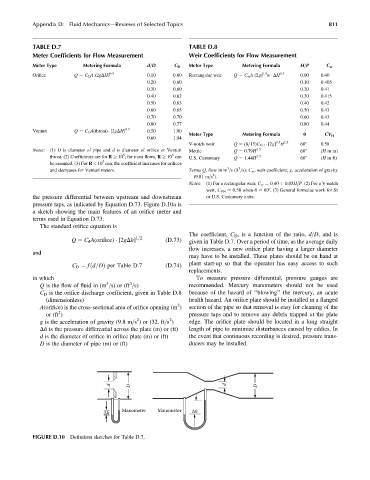

pressure taps, as indicated by Equation D.73. Figure D.10a is

a sketch showing the main features of an orifice meter and

terms used in Equation D.73.

The standard orifice equation is

The coefficient, C D , is a function of the ratio, d=D, and is

Q ¼ C d A(orifice) [2gDh] 1=2 (D:73) given in Table D.7. Over a period of time, as the average daily

flow increases, a new orifice plate having a larger diameter

and

may have to be installed. These plates should be on hand at

Þ per Table D:7 (D:74) plant start-up so that the operator has easy access to such

C D ¼ fd=Dð

replacements.

in which To measure pressure differential, pressure gauges are

3

3

Q is the flow of fluid in (m =s) or (ft =s) recommended. Mercury manometers should not be used

C D is the orifice discharge coefficient, given in Table D.8 because of the hazard of ‘‘blowing’’ the mercury, an acute

(dimensionless) health hazard. An orifice plate should be installed in a flanged

2

A(orifice) is the cross-sectional area of orifice opening (m ) section of the pipe so that removal is easy for cleaning of the

2

or (ft ) pressure taps and to remove any debris trapped at the plate

2

2

g is the acceleration of gravity (9.8 m=s ) or (32. ft=s ) edge. The orifice plate should be located in a long straight

Dh is the pressure differential across the plate (m) or (ft) length of pipe to minimize disturbances caused by eddies. In

d is the diameter of orifice in orifice plate (m) or (ft) the event that continuous recording is desired, pressure trans-

D is the diameter of pipe (m) or (ft) ducers may be installed.

d D d D

Manometer Manometer Δh

Δh

FIGURE D.10 Definition sketches for Table D.7.