Page 879 - Fundamentals of Water Treatment Unit Processes : Physical, Chemical, and Biological

P. 879

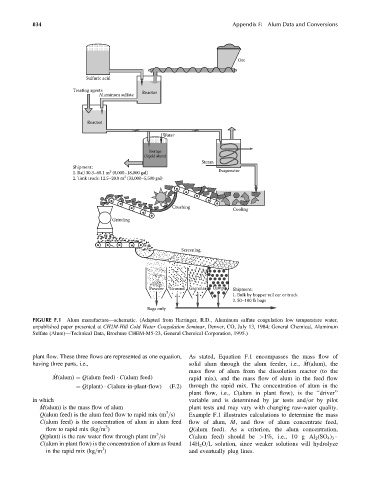

834 Appendix F: Alum Data and Conversions

Ore

Sulfuric acid

Treating agents Reactor

Aluminum sulfate

Reactor

Water

Storage

(liquid alum)

Steam

Shipment:

3

1. Rail 30.3–68.1 m (8,000–18,000 gal) Evaporator

3

2. Tank truck: 12.5–20.8 m (33,000–5,500 gal)

Crushing

Cooling

Grinding

Screening

Powder Ground Granular Lump Shipment:

1. Bulk by hopper rail car or truck

2. 50–100 lb bags

Bags only

FIGURE F.1 Alum manufacture—schematic. (Adapted from Harringer, R.D., Aluminum sulfate coagulation low temperature water,

unpublished paper presented at CH2M-Hill Cold Water Coagulation Seminar, Denver, CO, July 13, 1984; General Chemical, Aluminum

Sulfate (Alum)—Technical Data, Brochure CHEM-M5-23, General Chemical Corporation, 1995.)

plant flow. These three flows are represented as one equation, As stated, Equation F.1 encompasses the mass flow of

_

having three parts, i.e., solid alum through the alum feeder, i.e., M(alum), the

mass flow of alum from the dissolution reactor (to the

_

M(alum) ¼ Q(alum feed) C(alum feed) rapid mix), and the mass flow of alum in the feed flow

¼ Q(plant) C(alum-in-plant-flow) (F:2) through the rapid mix. The concentration of alum in the

plant flow, i.e., C(alum in plant flow), is the ‘‘driver’’

in which variable and is determined by jar tests and=or by pilot

_

M(alum) is the mass flow of alum plant tests and may vary with changing raw-water quality.

3

Q(alum feed) is the alum feed flow to rapid mix (m =s) Example F.1 illustrates calculations to determine the mass

_

C(alum feed) is the concentration of alum in alum feed flow of alum, M,and flow of alum concentrate feed,

3

flow to rapid mix (kg=m ) Q(alum feed). As a criterion, the alum concentration,

3

Q(plant) is the raw water flow through plant (m =s) C(alum feed) should be >1%,i.e.,10gAl 2 (SO 4 ) 3

C(alum in plant flow) is the concentration of alum as found 14H 2 O=L solution, since weaker solutions will hydrolyze

3

in the rapid mix (kg=m ) and eventually plug lines.