Page 147 - Gas Purification 5E

P. 147

136 Gas Purification

I

I

I \

I \

I \

I I

! LeanAmine

WL I TL, C~L,

L,,

! LLC02’LLHzS

\

\

\

I \

I \

I

I

2.. ;

I

I

/

I

I

Enthalpy

I

Balance

Envelope

I

I

I

I

I

I

I

I

I

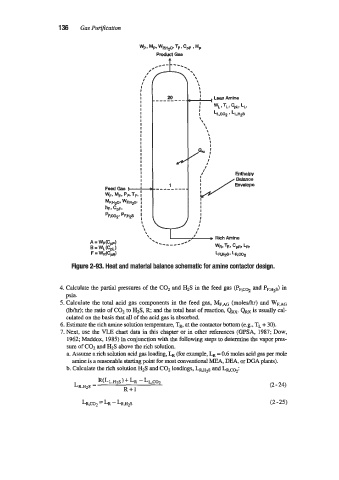

Figure 2-93. Heat and material balance schematic for amine contactor design.

4. Calculate the partial pressures of the C02 and H2S in the feed gas (PF,coz and PF.H2~)

in

psia.

5. Calculate the total acid gas components in the feed gas, MF,AG (moleshr) and WF.*~

(Iblhr); the ratio of C02 to H2S, R; and the total heat of reaction, QRx. QRx is usually cal-

culated on the basis that all of the acid gas is absorbed.

6. Estimate the rich amine solution temperature, TR, at the contactor bottom (e.g.? TL + 30).

7. Next, use the VLE chart data in this chapter or in other references (GPSA, 1987; Dow,

1962; Maddox, 1985) in conjunction with the following steps to determine the vapor pres-

sure of C02 and HIS above the rich solution.

a. Assume a rich solution acid gas loading, r, (for example, r, = 0.6 moles acid gas per mole

amine is a reasonable skuting point for most conventional MEA, DEA, or JXA plants).

b. Calculate the rich solution H2S and C02 loadings, LR,H~S and LR,c%:

(2 - 24)

LR,CO-, = LR - LR,H2S (2-25)