Page 184 - Gas Purification 5E

P. 184

Alhnolaniines jor Hydrogen Sulfide and Carbon Dio-xide Renioval 171

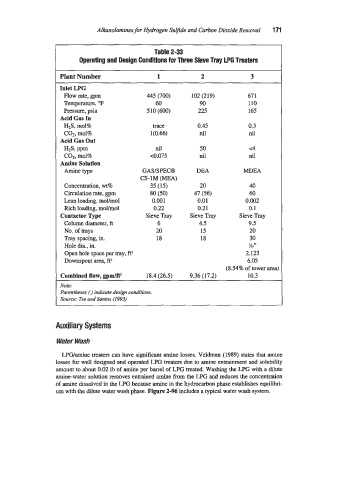

Table 2-33

Operating and Design Conditions for Three Sieve Tray LPG Treaters

Plant Number 1 2 3

Inlet LPG

Flow rate, gpm 445 (700) 102 (219) 67 1

Temperature, OF 60 90 110

Pressure, psia 510 (600) 225 165

Acid Gas In

H2S, mol% trace 0.45 0.3

CO2, mol% l(0.66) nil nil

Acid Gas Out

H2S, ppm nil 50 <4

C02, mol% ~0.075 nil nil

Amine Solution

Amine type GASISPECB DEA MDEA

CS-1M (MEA)

Concentration, wt% 35 (15j 20 40

Circulation rate, gpm 80 (50) 47 (56) 60

Lean loading, mol/mol 0.001 0.01 0.002

Rich loading, moYmol 0.22 0.2 1 0.1

Contactor Type Sieve Tray Sieve Tray Sieve Tray

Column diameter, ft 6 4.5 9.5

No. of trays 20 15 20

Tray spacing, in. 18 18 30

Hole dia., in. X6t!

Open hole space per tray, fi2 2.123

Downspout area, ff 6.05

-.

.,

Combined flow. mdff 18.4 (26.5) 9.36 (17.2) (8.54% of tower area)

10.3

.

I

Note:

Parentheses () indicate design conditions.

Source: Tse and Santos (1993)

Auxiliary Systems

Water Wash

LPGlamine maters can have significant amine losses. Veldman (1989) states that amine

losses for well designed and operated LPG treaters due to amine entrainment and solubility

amount to about 0.02 lb of amine per barrel of LPG treated. Washing the LPG with a dilute

amine-water solution removes entrained amine from the LPG and reduces the concentration

of amine dissolved in the LPG because amine in the hydrocarbon phase establishes equilibri-

um with the dilute water wash phase. Figure 2-96 includes a typical water wash system.