Page 228 - Gas Purification 5E

P. 228

214 Gas Purification

~

Table 3-5

Recommended Maximum Amine Solution Piping Velocities

for Rich and Lean Amine Solutions

~

Velocity, dsec (fthec) (Note 1)

I Amine Rich Solution Lean Solution Reference

All 1.8 (6) 1.8 (6) API, 1990

All 0.9 (3) 0.9 (3) Campbell, 1981

MEA 0.9 (3) 0.9 (3) Dingman et al., 1966

All 1.5 (5) - Dupart et al., 1993B

DEA (Note2) 1.0 (3.3) - Dailey, 1970

DEA (Note 2) 0.9 (3.0) - Smith and Younger, 1972

DGA 1.5 (5) 1.5 (5) Seubert and Wallace, 1985

All 0.6-1.5 (2-5) 0.6-1.5 (2-5) Manning and Thompson, 1991

Notes:

I. Figures also generally apply to heat exchanger tubing. However, Manning and Thompson (1991)

recommend a maximum tubeside velocity of 2 to 4ft/sec for leadrich exchangers where rich amine

is on the tubeside.

2. Recommended velocity applies only to rich DEAJowing through the tubeside of a leadrich

exchanger. Dailey (1970) and Smith and Younger (1972) report that severe corrosion occurred in

the tubes of a leadrich exchanger when the tubeside velocity exceeded 5.25ft/ec.

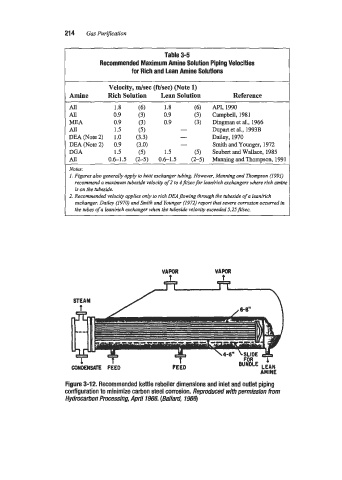

VAPOR VAPOR

STEAM

Figure 3-1 2. Recommended kettle reboiler dimensions and inlet and outlet piping

configuration to minimize carbon steel corrosion. Reproduced with permission from

Hydmaaon PmessinQ, April 1966. (Ballard, 1966)