Page 229 - Gas Purification 5E

P. 229

Mechanical Design and Operation of Alkanolamine Plants 21 5

Sheilan and Smith (1984) recommend perforated inlet baffles for heat exchangers to prevent

corrosion due to impingement. Ballard (1966), Dingman et al. (1966), and Connors (1958)

suggest designing reboilers with liberal disengaging space to minimize violent boiling and

resulting erosion-corrosion. All recommend removal of tube rows to form a ‘V or “X” in

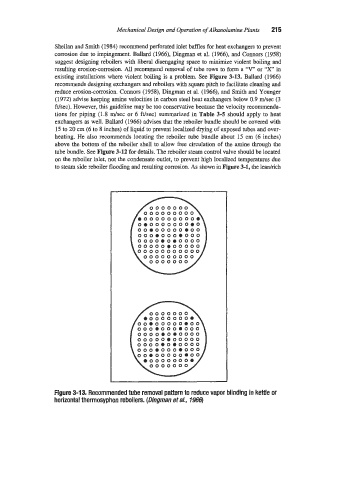

existing installations where violent boiling is a problem. See Figure 3-13. Ballad (1966)

recommends designing exchangers and reboilers with square pitch to facilitate cleaning and

reduce erosion-corrosion. Connors (1958), Dingman et al. (1966), and Smith and Younger

(1972) advise keeping amine velocities in carbon steel heat exchangers below 0.9 dsec (3

ft/sec). However, this guideline may be too conservative because the velocity recommenda-

tions for piping (1.8 dsec or 6 ft/sec) summarized in Table 3-5 should apply to heat

exchangers as well. Ballard (1966) advises that the reboiler bundle should be covered with

15 to 20 cm (6 to 8 inches) of liquid to prevent localized drying of exposed tubes and over-

heating. He also recommends locating the reboiler tube bundle about 15 cm (6 inches)

above the bottom of the reboiler shell to allow free circulation of the amine through the

tube bundle. See Figure 3-12 for details. The reboiler steam control valve should be located

on the reboiler inlet, not the condensate outlet, to prevent high localized temperatures due

to steam side reboiler flooding and resulting corrosion. As shown in Figure 3-1, the ledrich

000000000

.000000000.

0.0000000.0

00.00000.00

000.000.000

0000.0.0000

00000.00000

0000000

.0000000.

00.00000.00

000.000.000

0000.0.0000

00000.00000

0000.0.0000

000.000.000

.0000000.

0000000

Figure 3-13. Recommended tube removal pattern to reduce vapor blinding in I kettle or

horizontal thermosyphon reboilers. (Dingman et al., 1966)