Page 226 - Gas Purification 5E

P. 226

21 2 Gas Pur8cation

Heat Stable Salt Neutralization. Soda ash (or caustic soda) is often added to DEA and

MDEA solutions to neutralize heat-stable salts, and there is considerable plant evidence that

this is an effective means of reducing corrosion (Smith and Younger, 1972; Butwell et al.,

1982; Liu and Gregory, 1994; Bums and Gregory, 1995; Liu et al., 1995; Rooney et al.,

1996). Adding soda ash reduces amine solution corrosiveness by raising the solution pH.

Soda ash addition may also reduce corrosion by preventing the release of weaker acids such

as formic acid during amine regeneration (McCullough and Nielsen, 1996). Although soda

ash addition can reduce corrosion, the amount that can be added is limited because solids

will eventually be precipitated, plugging equipment and piping. However, solids precipita-

tion and equipment plugging can be avoided if soda ash addition is combined with amine

solution reclaiming using either batch distillation, ion exchange, or electrodialysis. Soda ash

addition is particularly attractive for secondary and tertiary amines like DEA and MDEA

since these amines cannot be reclaimed during normal operation. Therefore, for these

amines, soda ash addition can be used to control corrosion until a contract reclaimer arrives

at the plant site.

According to Scheinnan (1973A, B), soda ash should first be added to DEA solutions

when the heat stable salt concentration reaches 0.5 wt%. Nearly 20 wt% sodium salts can be

tolerated before any solids precipitate. Potassium carbonate can also be used to neutralize

heat stable salts and has the advantage of being about 25% more soluble by weight than sodi-

um compounds (Scheirman, 1973A, B).

For MDEA solutions, Liu and Gregory (1994) recommend that soda ash should be added

to keep the amine heat stable salts concentration below 2 wt%. The MDEA solution should

be reclaimed when the total heat stable salt anion content reaches 4 wt%. Rooney et al.

(1996) have also investigated caustic soda neutralization of MDEA solutions containing heat

stable amine salts. They recommend that soda ash addition be used to keep the heat stable

amine salts level below 0.5 wt%. In addition, they recommend that individual heat stable

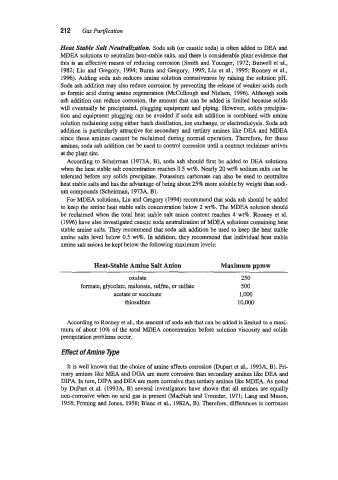

amine salt anions be kept below the following maximum levels:

Heat-Stable Amine Salt Anion Maximum ppmw

oxalate 250

formate, glycolate, malonate, sulfite, or sulfate 500

acetate or succinate 1,000

thiosulfate 10.000

According to Rooney et al., the amount of soda ash that can be added is limited to a maxi-

mum of about 10% of the total MDEA concentration before solution viscosity and solids

precipitation problems occur.

Effect of Amine vpe

It is well known that the choice of amine affects corrosion (Dupart et al., 1993A, B). Pri-

mary amines like MEA and DGA are more corrosive than secondary amines like DEA and

DIPA. In turn, DIPA and DEA ace more corrosive than tertiary amines like MDEA. As noted

by DuPart et al. (1993A, B) several investigators have shown that all amines are equally

non-corrosive when no acid gas is present (MacNab and Treseder, 1971; Lang and Mason,

1958; Froning and Jones, 1958; Blanc et al., 1982A, B). Therefore, differences in corrosion