Page 257 - Gas Purification 5E

P. 257

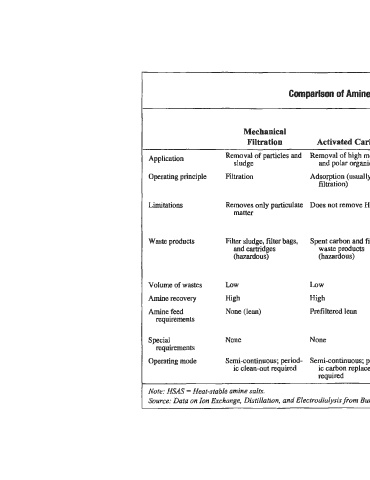

Table 3-6

Comparison of Amine Solution Purlfication Techniques

Distillation

Mechanical (thermal

Filtration Activated Carbon reclaiming) Ion Exchange Electrodialysis

Application Removal of particles and Removal of high mol. wt. Removal of all solids and Removal of ionized Removal of ionized

nonvolatile species

impuntie$

sludge

and polar organics

impurities

Operating principle Filtration Adsorption (usually with Vaporization of volatile Ions am captured by ion Ions are moved by elec-

filtration) species (amine, water, exchange resin tricity from amine to

etc.) waste soh.

Limitations Removes only paaiculate Does not remove HSAS Energy intensiye. Some Does not remove nonion- Does not remove

matter amines requlre ic species. Best for nonionic species.

vacuum low salt conc. Best for moderate

to high salt concs.

Waste products Filter sludge, filter bags, Spent carbon and filter Reclaimer bottoms, con- Dilute aqueous stream Brine containing

and cartridges waste products taining salts, non- containing removed removed ions

(hazardous) (hazardous) volatile qrganics and ions plus excess regen-

some amine eration and rinse water

(hazardous)

High -

Volume of wastes LOW LOW LOW High (about 99%) Moderate

Amine recovery High High Moderate (about 85-9591 High (about 98%)

Cool, lean, hydrocarbon

Amine feed None (lean) Prefiltered lean HSAS neutralized and particulate free Cool, lean, hydrocarbon

requirements and particulate free;

Regeneration chemicals HSAS neutralized

I

Spid None None Fuel gas or high temp. D.C. power supply

requirements heat source

Semi-continuous, batch or

Operating mode Semi-continuous; period- Semi-continuous; period- Batch or on-line; mobile on-line, mobile units Continuous on-line,

ic clean-out required ic carbon replacement units available available or batch, mobile units

required a v ai 1 ab 1 e

~~

Note: HSAS = Heat-stable amine salts.

Source: Data on Ion Exchange, DistiIlution, and Electmdiulysis from Burns and Gregory (1995)