Page 253 - Gas Purification 5E

P. 253

Mechanical Design and Operation of Alkanolamine Plants 239

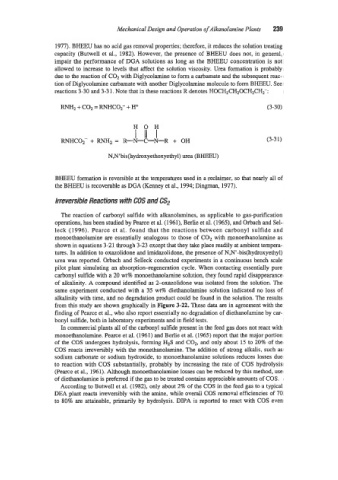

1977). BHEEU has no acid gas removal properties; therefore, it reduces the solution treating

capacity (Butwell et al., 1982). However, the presence of BHEEU does not, in general,

impair the performance of DGA solutions as long as the BHEEU concentration is not

allowed to increase to levels that affect the solution viscosity. Urea formation is probably

due to the reaction of C02 with Diglycolamine to form a carbamate and the subsequent reac-

tion of Diglycolamine carbamate with another Diglycolamine molecule to form BHEEU. See

reactions 3-30 and 3-31. Note that in these reactions R denotes HOCH2CH20CH2CH,-:

RNH, + C02 = RNHCOZ- + H+ (3-30)

HOH

I II 1

RNHCOl+ RNHz = R-N-C-N-R + OH (3-3 1)

N,N'bis(hydroxyethoxyethyl) urea (BHEEU)

BHEEU formation is reversible at the temperatures used in a reclaimer, so that nearly all of

the BHEiEU is recoverable as DGA (Kenney et al., 1994; Dingman, 1977).

ImvemWe Reactions with COS and &S2

The reaction of carbonyl sulfide with alkanolamines, as applicable to gas-purification

operations, has been studied by Pearce et al. (1961), Berlie et al. (1963, and Orbach and Sel-

leck (1996). Pearce et al. found that the reactions between carbonyl sulfide and

monoethanolamine are essentially analogous to those of C02 with monoethanolamine as

shown in equations 3-21 through 3-23 except that they take place readily at ambient tempera-

tures. In addition to oxazolidone and imidazolidone, the presence of N,N'-bis(hydroxyethy1)

urea was reported. Orbach and Selleck conducted experiments in a continuous bench scale

pilot plant simulating an absorption-regeneration cycle. When contacting essentially pure

carbonyl sulfide with a 20 wt% monoethanolamine solution, they found rapid disappearance

of alkalinity. A compound identified as 2-oxazolidone was isolated from the solution. The

same experiment conducted with a 35 wt% diethanolamine solution indicated no loss of

alkalinity with time, and no degradation product could be found in the solution. The results

from this study are shown graphically in Figure 3-22. These data are in agreement with the

finding of Pearce et al., who also report essentially no degradation of diethanolamine by car-

bonyl sulfide, both in laboratory experiments and in field tests.

In commercial plants all of the carbonyl sulfide present in the feed gas does not react with

monoethanolamine. Pearce et al. (1961) and Berlie et al. (1965) report that the major portion

of the COS undergoes hydrolysis, forming H2S and Cot and only about 15 to 20% of the

COS reacts irreversibly with the monethanolamine. The addition of strong alkalis, such as

sodium carbonate or sodium hydroxide, to monoethanolamine solutions reduces losses due

to reaction with COS substantially, probably by increasing the rate of COS hydrolysis

(Pearce et al., 1961). Although monoethanolamine losses can be reduced by this method, use

of diethanolamine is preferred if the gas to be treated contains appreciable amounts of COS.

According to Butwell et al. (1982), only about 2% of the COS in the feed gas to a typical

DEA plant reacts irreversibly with the amine, while overall COS removal efficiencies of 70

to 80% are attainable, primarily by hydrolysis. DIPA is reported to react with COS even