Page 271 - Gas Purification 5E

P. 271

Mechanical Design and Operation of Alkanolamine Plants 255

bed exceeds 40 psi. Upstream and downstream mechanical filtration are recommended when

the filter is used on a 10 to 20% slipstream. When the filter is used for full flow filtration, the

carbon filter acts as a mechanical filter, and no mechanical prefilter is required.

Thermal Reclaiming

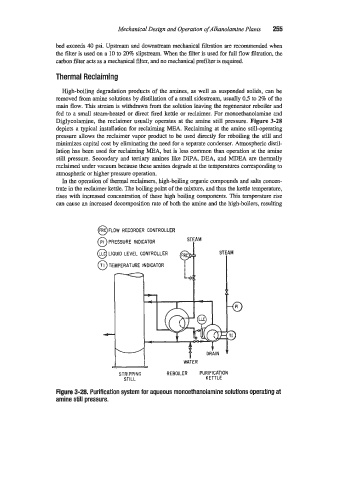

High-boiling degradation products of the amines, as well as suspended solids, can be

removed from amine solutions by distillation of a small sidestream, usually 0.5 to 2% of the

main flow. This stream is withdrawn from the solution leaving the regenerator reboiler and

fed to a small steam-heated or direct fired kettle or reclaimer. For monoethanolamine and

Diglycolamine, the reclaimer usually operates at the amine still pressure. Figure 3-28

depicts a typica1 installation for reclaiming MEA. Reclaiming at the amine still-operating

pressure allows the reclaimer vapor product to be used directly for reboiling the still and

minimizes capital cost by eliminating the need for a separate condenser. Atmospheric distil-

lation has been used for reclaiming MEA, but is less common than operation at the amine

still pressure. Secondary and tertiary amines like DIPA, DEA, and MDEA are thermally

reclaimed under vacuum because these amines degrade at the temperatures corresponding to

atmospheric or higher pressure operation.

In the operation of thermal reclaimers, high-boiling organic compounds and salts concen-

trate in the reclaimer kettle. The boiling point of the mixture, and thus the kettle temperature,

rises with increased concentration of these high boiling components. This temperature rise

can cause an increased decomposition rate of both the amine and the high-boilers, resulting

@FLOW RECORDER CONTROLLER

0

@PRESSURE INDICATOR STEAM

@LIQUID LEVEL CONTROLLER STEAM

@TEMPERATURE INDICATOR

STRIPPING REBOILER PURIFICATION

STILL KETTLE

Figure 3-28. Purification system for aqueous monoethanolamine solutions operating at

amine still pressure.