Page 275 - Gas Purification 5E

P. 275

Mechanical Design and weration ofAlkanolamine Plants 259

Vapors to OGA Slripper

t

Steam Condensate or OGA Skipper Reflux

if required lo limit kelUe temperature

lo 380°F. may.

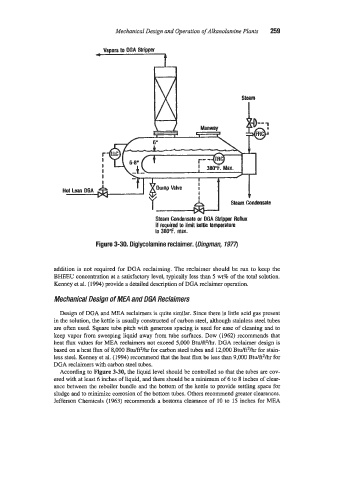

Figure 3-30. Diglycolamine reclaimer. (Dingman, 7977)

addition is not required for DGA reclaiming. The reclaimer should be run to keep the

BHEEU concentration at a satisfactory level, typically less than 5 wt% of the total solution.

Kenney et al. (1994) provide a detailed description of DGA reclaimer operation.

Mechanical Design of MEA and D[bA Reclaimers

Design of DGA and MEA reclaimem is quite similar. Since theE is little acid gas present

in the solution, the kettle is usually constructed of carbon steel, although stainless steel tubes

are often used. Square tube pitch with generous spacing is used for ease of cleaning and to

keep vapor from sweeping liquid away from tube surfaces. Dow (1962) recommends that

heat flux values for MEA reclaimers not exceed 5,000 Btu/f$/hr. DGA reclaimer design is

based on a heat flux of 8,000 Btu/ftz/hr for carbon steel tubes and 12,000 Btu/ftzh for stain-

less steel. Kenney et al. (1994) recommend that the heat flux be less than 9,000 Btu/ft2/hr for

DGA reclaimers with carbon steel tubes.

According to Figure 3-30, the liquid level should be controlled so that the tubes are cov-

ered with at least 6 inches of liquid, and there should be a minimum of 6 to 8 inches of clear-

ance between the reboiler bundle and the bottom of the kettle to provide settling space for

sludge and to minimize corrosion of the bottom tubes. Others recommend greater clearances.

Jefferson Chemicals (1963) recommends a bottoms clearance of 10 to 15 inches for MEA