Page 279 - Gas Purification 5E

P. 279

Mechanical Design and Operation of Alkanolarnine Plants 263

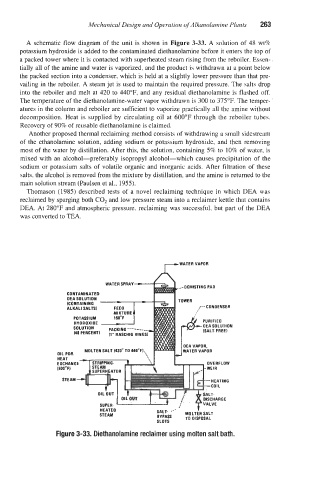

A schematic flow diagram of the unit is shown in Figure 3-33. A solution of 48 wt%

potassium hydroxide is added to the contaminated diethanolamine before it enters the top of

a packed tower where it is contacted with superheated steam rising from the reboiler. Essen-

tially all of the amine and water is vaporized, and the product is withdrawn at a point below

the packed section into a condenser, which is held at a slightly lower pressure than that pre-

vailing in the reboiler. A steam jet is used to maintain the required pressure. The salts drop

into the reboiler and melt at 420 to 440"F, and any residual diethanolamine is flashed off.

The temperature of the diethanolamine-water vapor withdrawn is 300 to 375°F. The temper-

atures in the column and reboiler are sufficient to vaporize practically all the amine without

decomposition. Heat is supplied by circulating oil at 600°F through the reboiler tubes.

Recovery of 90% of reusable diethanolamine is claimed.

Another proposed thermal reclaiming method consists of withdrawing a small sidestream

of the ethanolamine solution, adding sodium or potassium hydroxide, and then removing

most of the water by distillation. After this, the solution, containing 5% to 10% of water, is

mixed with an alcohol-preferably isopropyl alcohol-which causes precipitation of the

sodium or potassium salts of volatile organic and inorganic acids. After filtration of these

salts, the alcohol is removed from the mixture by distillation, and the amine is returned to the

main solution stream (Paulsen et al., 1955).

Thomason (1985) described tests of a novel reclaiming technique in which DEA was

reclaimed by sparging both C02 and low pressure steam into a reclaimer kettle that contains

DEA. At 280°F and atmospheric pressure, reclaiming was successful, but part of the DEA

was converted to TEA.

WATER SPRAY

,-DEMISTING PA0

CONTAMINATED

,P-- CONDENSER

WATER VAPOR

Figure 3-33. Diethanolamine reclaimer using molten salt bath.