Page 278 - Gas Purification 5E

P. 278

262 GasPuriJcation

4

STEAM

I

CONDENSER VACUUM

PUMP

STRIPPING REBOILER PURIFICATION CONDENSATE CONDENSAT- E

STILL KETTLE PUMP ACCUMULATOR

@ PRESSURE INDICATOR @ TEMPERATURE INDICATOR

0 INDICATOR @ TEMPERATURE RECORDER CONTROLLER

FLOW

@ LIQUID LEVEL CONTROLLER

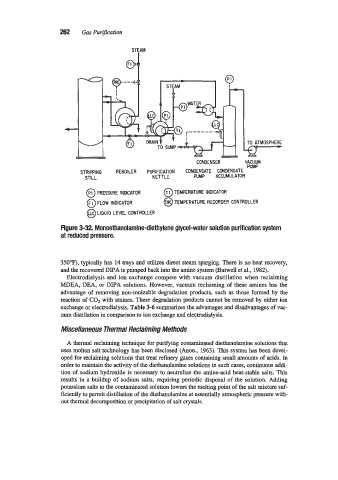

Figure 3-32. Monoethanolamine-diethylene glycol-water solution purification system

at reduced pressure.

350"F), typically has 14 trays and utilizes direct steam sparging. There is no heat recovery,

and the recovered DIPA is pumped back into the amine system (Butwell et al., 1982).

Electrodialysis and ion exchange compete with vacuum distillation when reclaiming

MDEA, DEA, or DIPA solutions. However, vacuum reclaiming of these amines has the

advantage of removing non-ionizable degradation products, such as those formed by the

reaction of COz with amines. These degradation products cannot be removed by either ion

exchange or electrodialysis. Table 3-6 summarizes the advantages and disadvantages of vac-

uum distillation in comparison to ion exchange and electrodialysis.

Miscellaneous Thermal Reclaiming Methods

A thermal reclaiming technique for purifying contaminated diethanolamine solutions that

uses molten salt technology has been disclosed (Anon., 1963). This system has been devel-

oped for reclaiming solutions that treat refinery gases containing small amounts of acids. In

order to maintain the activity of the diethanolamine solutions in such cases, continuous addi-

tion of sodium hydroxide is necessary to neutralize the amine-acid heat-stable salts. This

results in a buildup of sodium salts, requiring periodic disposal of the solution. Adding

potassium salts to the contaminated solution lowers the melting point of the salt mixture suf-

ficiently to permit distillation of the diethanolamine at essentially atmospheric pressure with-

out thermal decomposition or precipitation of salt crystals.