Page 232 - Geothermal Energy Renewable Energy and The Environment

P. 232

220 Geothermal Energy: Renewable Energy and the Environment

District heating

distribution

line

Discharge line

500 meters

Discharge point

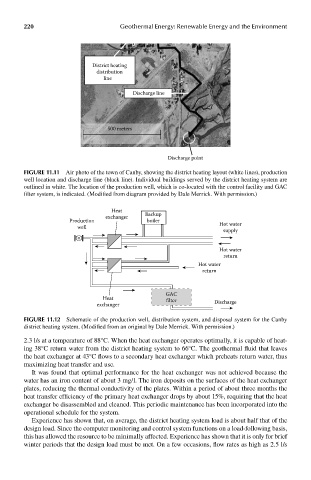

FIGUre 11.11 Air photo of the town of Canby, showing the district heating layout (white lines), production

well location and discharge line (black line). Individual buildings served by the district heating system are

outlined in white. The location of the production well, which is co-located with the control facility and GAC

filter system, is indicated. (Modified from diagram provided by Dale Merrick. With permission.)

Heat

exchanger Backup

Production boiler Hot water

well

supply

Hot water

return

Hot water

return

GAC

Heat filter

exchanger Discharge

FIGUre 11.12 Schematic of the production well, distribution system, and disposal system for the Canby

district heating system. (Modified from an original by Dale Merrick. With permission.)

2.3 l/s at a temperature of 88°C. When the heat exchanger operates optimally, it is capable of heat-

ing 38°C return water from the district heating system to 66°C. The geothermal fluid that leaves

the heat exchanger at 43°C flows to a secondary heat exchanger which preheats return water, thus

maximizing heat transfer and use.

It was found that optimal performance for the heat exchanger was not achieved because the

water has an iron content of about 3 mg/l. The iron deposits on the surfaces of the heat exchanger

plates, reducing the thermal conductivity of the plates. Within a period of about three months the

heat transfer efficiency of the primary heat exchanger drops by about 15%, requiring that the heat

exchanger be disassembled and cleaned. This periodic maintenance has been incorporated into the

operational schedule for the system.

Experience has shown that, on average, the district heating system load is about half that of the

design load. Since the computer monitoring and control system functions on a load-following basis,

this has allowed the resource to be minimally affected. Experience has shown that it is only for brief

winter periods that the design load must be met. On a few occasions, flow rates as high as 2.5 l/s