Page 100 - Global Project Management Handbook

P. 100

4-8 STATE OF THE ART OF GLOBAL PROJECT MANAGEMENT

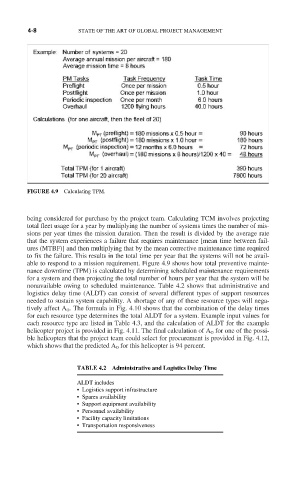

FIGURE 4.9 Calculating TPM.

being considered for purchase by the project team. Calculating TCM involves projecting

total fleet usage for a year by multiplying the number of systems times the number of mis-

sions per year times the mission duration. Then the result is divided by the average rate

that the system experiences a failure that requires maintenance [mean time between fail-

ures (MTBF)] and then multiplying that by the mean corrective maintenance time required

to fix the failure. This results in the total time per year that the systems will not be avail-

able to respond to a mission requirement. Figure 4.9 shows how total preventive mainte-

nance downtime (TPM) is calculated by determining scheduled maintenance requirements

for a system and then projecting the total number of hours per year that the system will be

nonavailable owing to scheduled maintenance. Table 4.2 shows that administrative and

logistics delay time (ALDT) can consist of several different types of support resources

needed to sustain system capability. A shortage of any of these resource types will nega-

tively affect A O . The formula in Fig. 4.10 shows that the combination of the delay times

for each resource type determines the total ALDT for a system. Example input values for

each resource type are listed in Table 4.3, and the calculation of ALDT for the example

helicopter project is provided in Fig. 4.11. The final calculation of A O for one of the possi-

ble helicopters that the project team could select for procurement is provided in Fig. 4.12,

which shows that the predicted A O for this helicopter is 94 percent.

TABLE 4.2 Administrative and Logistics Delay Time

ALDT includes

• Logistics support infrastructure

• Spares availability

• Support equipment availability

• Personnel availability

• Facility capacity limitations

• Transportation responsiveness