Page 102 - Global Project Management Handbook

P. 102

4-10 STATE OF THE ART OF GLOBAL PROJECT MANAGEMENT

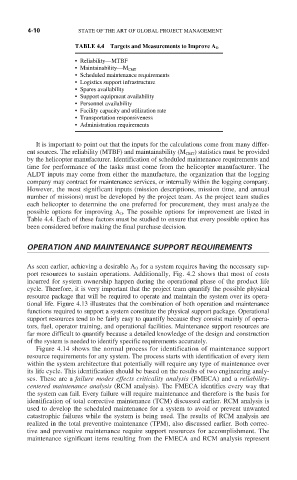

TABLE 4.4 Targets and Measurements to Improve A O

• Reliability—MTBF

• Maintainability—M CMT

• Scheduled maintenance requirements

• Logistics support infrastructure

• Spares availability

• Support equipment availability

• Personnel availability

• Facility capacity and utilization rate

• Transportation responsiveness

• Administration requirements

It is important to point out that the inputs for the calculations come from many differ-

ent sources. The reliability (MTBF) and maintainability (M CMT ) statistics must be provided

by the helicopter manufacturer. Identification of scheduled maintenance requirements and

time for performance of the tasks must come from the helicopter manufacturer. The

ALDT inputs may come from either the manufacture, the organization that the logging

company may contract for maintenance services, or internally within the logging company.

However, the most significant inputs (mission descriptions, mission time, and annual

number of missions) must be developed by the project team. As the project team studies

each helicopter to determine the one preferred for procurement, they must analyze the

possible options for improving A O . The possible options for improvement are listed in

Table 4.4. Each of these factors must be studied to ensure that every possible option has

been considered before making the final purchase decision.

OPERATION AND MAINTENANCE SUPPORT REQUIREMENTS

As seen earlier, achieving a desirable A O for a system requires having the necessary sup-

port resources to sustain operations. Additionally, Fig. 4.2 shows that most of costs

incurred for system ownership happen during the operational phase of the product life

cycle. Therefore, it is very important that the project team quantify the possible physical

resource package that will be required to operate and maintain the system over its opera-

tional life. Figure 4.13 illustrates that the combination of both operation and maintenance

functions required to support a system constitute the physical support package. Operational

support resources tend to be fairly easy to quantify because they consist mainly of opera-

tors, fuel, operator training, and operational facilities. Maintenance support resources are

far more difficult to quantify because a detailed knowledge of the design and construction

of the system is needed to identify specific requirements accurately.

Figure 4.14 shows the normal process for identification of maintenance support

resource requirements for any system. The process starts with identification of every item

within the system architecture that potentially will require any type of maintenance over

its life cycle. This identification should be based on the results of two engineering analy-

ses. These are a failure modes effects criticality analysis (FMECA) and a reliability-

centered maintenance analysis (RCM analysis). The FMECA identifies every way that

the system can fail. Every failure will require maintenance and therefore is the basis for

identification of total corrective maintenance (TCM) discussed earlier. RCM analysis is

used to develop the scheduled maintenance for a system to avoid or prevent unwanted

catastrophic failures while the system is being used. The results of RCM analysis are

realized in the total preventive maintenance (TPM), also discussed earlier. Both correc-

tive and preventive maintenance require support resources for accomplishment. The

maintenance significant items resulting from the FMECA and RCM analysis represent