Page 98 - Global Project Management Handbook

P. 98

4-6 STATE OF THE ART OF GLOBAL PROJECT MANAGEMENT

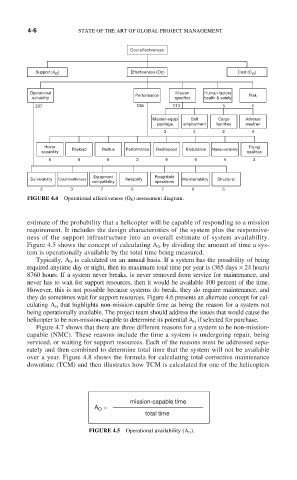

Cost effectiveness

Support (A ) Effectiveness (O E ) Cost (C )

O

O

Operational Performance Mission Human factors Risk

suitability specifics health & safety

Σ37 Σ38 Σ13 5 5

Mission equip Self Cargo Adverse

package employment facilities weather

3 4 2 4

Hover Flying

capability Payload Radius Performance Dashspeed Endurance Maneuverability qualities

6 6 6 3 4 6 4 3

Equipment Roughfield

Survivability Crashworthiness Reliability Maintainability Structural

compatibility operations

3 3 7 6 7 6 5

FIGURE 4.4 Operational effectiveness (O E ) assessment diagram.

estimate of the probability that a helicopter will be capable of responding to a mission

requirement. It includes the design characteristics of the system plus the responsive-

ness of the support infrastructure into an overall estimate of system availability.

Figure 4.5 shows the concept of calculating A O by dividing the amount of time a sys-

tem is operationally available by the total time being measured.

Typically, A O is calculated on an annual basis. If a system has the possibility of being

required anytime day or night, then its maximum total time per year is (365 days × 24 hours)

8760 hours. If a system never breaks, is never removed from service for maintenance, and

never has to wait for support resources, then it would be available 100 percent of the time.

However, this is not possible because systems do break, they do require maintenance, and

they do sometimes wait for support resources. Figure 4.6 presents an alternate concept for cal-

culating A O that highlights non-mission-capable time as being the reason for a system not

being operationally available. The project team should address the issues that would cause the

helicopter to be non-mission-capable to determine its potential A O if selected for purchase.

Figure 4.7 shows that there are three different reasons for a system to be non-mission-

capable (NMC). These reasons include the time a system is undergoing repair, being

serviced, or waiting for support resources. Each of the reasons must be addressed sepa-

rately and then combined to determine total time that the system will not be available

over a year. Figure 4.8 shows the formula for calculating total corrective maintenance

downtime (TCM) and then illustrates how TCM is calculated for one of the helicopters

mission-capable time

A =

O

total time

FIGURE 4.5 Operational availability (A O ).