Page 556 - Handbook of Thermal Analysis of Construction Materials

P. 556

526 Chapter 12 - Clay-Based Construction Products

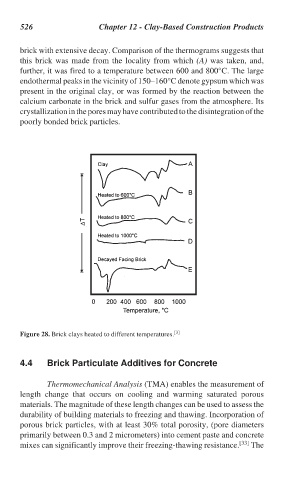

brick with extensive decay. Comparison of the thermograms suggests that

this brick was made from the locality from which (A) was taken, and,

further, it was fired to a temperature between 600 and 800°C. The large

endothermal peaks in the vicinity of 150–160°C denote gypsum which was

present in the original clay, or was formed by the reaction between the

calcium carbonate in the brick and sulfur gases from the atmosphere. Its

crystallization in the pores may have contributed to the disintegration of the

poorly bonded brick particles.

Figure 28. Brick clays heated to different temperatures. [3]

4.4 Brick Particulate Additives for Concrete

Thermomechanical Analysis (TMA) enables the measurement of

length change that occurs on cooling and warming saturated porous

materials. The magnitude of these length changes can be used to assess the

durability of building materials to freezing and thawing. Incorporation of

porous brick particles, with at least 30% total porosity, (pore diameters

primarily between 0.3 and 2 micrometers) into cement paste and concrete

mixes can significantly improve their freezing-thawing resistance. [33] The