Page 558 - Handbook of Thermal Analysis of Construction Materials

P. 558

528 Chapter 12 - Clay-Based Construction Products

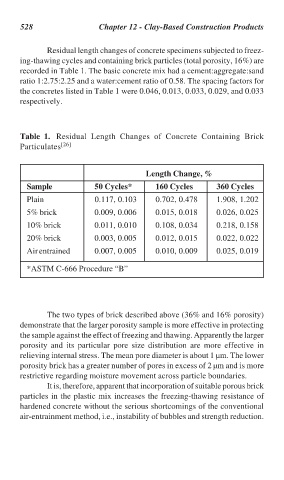

Residual length changes of concrete specimens subjected to freez-

ing-thawing cycles and containing brick particles (total porosity, 16%) are

recorded in Table 1. The basic concrete mix had a cement:aggregate:sand

ratio 1:2.75:2.25 and a water:cement ratio of 0.58. The spacing factors for

the concretes listed in Table 1 were 0.046, 0.013, 0.033, 0.029, and 0.033

respectively.

Table 1. Residual Length Changes of Concrete Containing Brick

Particulates [26]

Length Change, %

Sample 50 Cycles* 160 Cycles 360 Cycles

Plain 0.117, 0.103 0.702, 0.478 1.908, 1.202

5% brick 0.009, 0.006 0.015, 0.018 0.026, 0.025

10% brick 0.011, 0.010 0.108, 0.034 0.218, 0.158

20% brick 0.003, 0.005 0.012, 0.015 0.022, 0.022

Air entrained 0.007, 0.005 0.010, 0.009 0.025, 0.019

*ASTM C-666 Procedure “B”

The two types of brick described above (36% and 16% porosity)

demonstrate that the larger porosity sample is more effective in protecting

the sample against the effect of freezing and thawing. Apparently the larger

porosity and its particular pore size distribution are more effective in

relieving internal stress. The mean pore diameter is about 1 µm. The lower

porosity brick has a greater number of pores in excess of 2 µm and is more

restrictive regarding moisture movement across particle boundaries.

It is, therefore, apparent that incorporation of suitable porous brick

particles in the plastic mix increases the freezing-thawing resistance of

hardened concrete without the serious shortcomings of the conventional

air-entrainment method, i.e., instability of bubbles and strength reduction.