Page 299 - HVAC Pump Handbook

P. 299

Rishel_CH10.qxd 21/4/06 6:20 PM Page 296

Basics of Pump Application for HVAC Systems

296 The HVAC World

This table demonstrates that, in this case, the three-pump system

provides a higher wire-to-water efficiency throughout the load range

than does the two-pump system of 2500-gal/min pumps. The actual

pump selection has some bearing on these results, so this should not

imply that in every case it would be more efficient to use three

instead of two pumps. Such a wire-to-water efficiency program should

be run on every application where substantial motor horsepowers are

involved. A significant fact that can be secured from this particular

calculation is that two pumps should be operated from 1000 gal/min

upward even though one pump could hand the water system up to

1685 gal/min.

10.8.3 Wire-to-water efficiency for

constant-speed pumps

Wire-to-water efficiency can be computed for both constant- and

variable-speed pumping systems. One of the unique advantages of

this program is the ability to compute the wire-to-water efficiency

for a pumping system with constant- and variable-speed pumping.

Table 10.6 describes the wire-to-water efficiency of the two-pump

constant-speed system. The pump curve of Fig. 10.11b applies in this

case, and only one pump runs at a time.

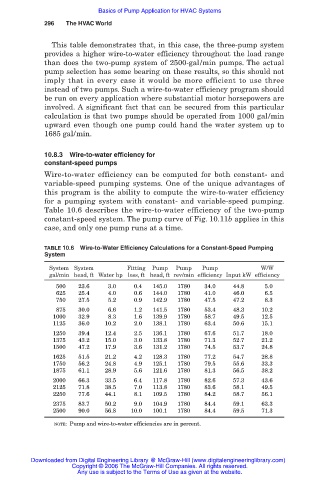

TABLE 10.6 Wire-to-Water Efficiency Calculations for a Constant-Speed Pumping

System

System System Fitting Pump Pump Pump W/W

gal/min head, ft Water hp loss, ft head, ft rev/min efficiency Input kW efficiency

0500 23.6 3.0 0.4 145.0 1780 34.0 44.8 5.0

0625 25.4 4.0 0.6 144.0 1780 41.0 46.0 6.5

0750 27.5 5.2 0.9 142.9 1780 47.5 47.2 8.3

0875 30.0 6.6 1.2 141.5 1780 53.4 48.3 10.2

1000 32.9 8.3 1.6 139.9 1780 58.7 49.5 12.5

1125 36.0 10.2 2.0 138.1 1780 63.4 50.6 15.1

1250 39.4 12.4 2.5 136.1 1780 67.6 51.7 18.0

1375 43.2 15.0 3.0 133.8 1780 71.3 52.7 21.2

1500 47.2 17.9 3.6 131.2 1780 74.5 53.7 24.8

1625 51.5 21.2 4.2 128.3 1780 77.2 54.7 28.8

1750 56.2 24.8 4.9 125.1 1780 79.5 55.6 33.3

1875 61.1 28.9 5.6 121.6 1780 81.3 56.5 38.2

2000 66.3 33.5 6.4 117.8 1780 82.6 57.3 43.6

2125 71.8 38.5 7.0 113.8 1780 83.6 58.1 49.5

2250 77.6 44.1 8.1 109.5 1780 84.2 58.7 56.1

2375 83.7 50.2 9.0 104.9 1780 84.4 59.1 63.3

2500 90.0 56.8 10.0 100.1 1780 84.4 59.5 71.3

NOTE: Pump and wire-to-water efficiencies are in percent.

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2006 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.