Page 96 - Handbook of Thermal Analysis of Construction Materials

P. 96

Section 3.0 - Clinkerization 79

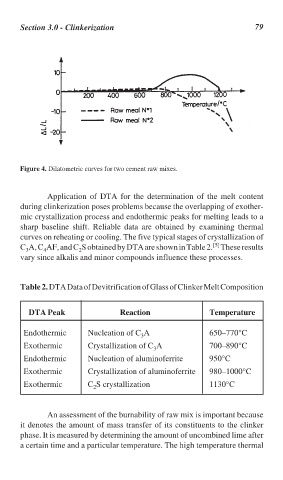

Figure 4. Dilatometric curves for two cement raw mixes.

Application of DTA for the determination of the melt content

during clinkerization poses problems because the overlapping of exother-

mic crystallization process and endothermic peaks for melting leads to a

sharp baseline shift. Reliable data are obtained by examining thermal

curves on reheating or cooling. The five typical stages of crystallization of

[5]

C A, C AF, and C S obtained by DTA are shown in Table 2. These results

2

4

3

vary since alkalis and minor compounds influence these processes.

Table 2. DTA Data of Devitrification of Glass of Clinker Melt Composition

DTA Peak Reaction Temperature

Endothermic Nucleation of C A 650–770°C

3

Exothermic Crystallization of C A 700–890°C

3

Endothermic Nucleation of aluminoferrite 950°C

Exothermic Crystallization of aluminoferrite 980–1000°C

Exothermic C S crystallization 1130°C

2

An assessment of the burnability of raw mix is important because

it denotes the amount of mass transfer of its constituents to the clinker

phase. It is measured by determining the amount of uncombined lime after

a certain time and a particular temperature. The high temperature thermal