Page 20 - Handbook of Adhesives and Sealants

P. 20

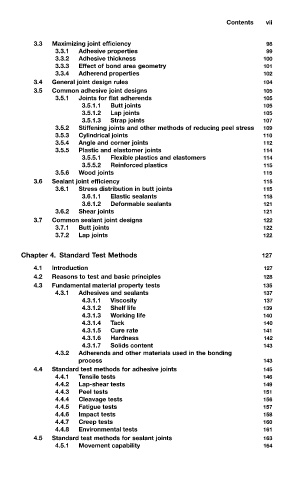

Contents vii

3.3 Maximizing joint efficiency 98

3.3.1 Adhesive properties 99

3.3.2 Adhesive thickness 100

3.3.3 Effect of bond area geometry 101

3.3.4 Adherend properties 102

3.4 General joint design rules 104

3.5 Common adhesive joint designs 105

3.5.1 Joints for flat adherends 105

3.5.1.1 Butt joints 105

3.5.1.2 Lap joints 105

3.5.1.3 Strap joints 107

3.5.2 Stiffening joints and other methods of reducing peel stress 109

3.5.3 Cylindrical joints 110

3.5.4 Angle and corner joints 112

3.5.5 Plastic and elastomer joints 114

3.5.5.1 Flexible plastics and elastomers 114

3.5.5.2 Reinforced plastics 115

3.5.6 Wood joints 115

3.6 Sealant joint efficiency 115

3.6.1 Stress distribution in butt joints 115

3.6.1.1 Elastic sealants 118

3.6.1.2 Deformable sealants 121

3.6.2 Shear joints 121

3.7 Common sealant joint designs 122

3.7.1 Butt joints 122

3.7.2 Lap joints 122

Chapter 4. Standard Test Methods 127

4.1 Introduction 127

4.2 Reasons to test and basic principles 128

4.3 Fundamental material property tests 135

4.3.1 Adhesives and sealants 137

4.3.1.1 Viscosity 137

4.3.1.2 Shelf life 139

4.3.1.3 Working life 140

4.3.1.4 Tack 140

4.3.1.5 Cure rate 141

4.3.1.6 Hardness 142

4.3.1.7 Solids content 143

4.3.2 Adherends and other materials used in the bonding

process 143

4.4 Standard test methods for adhesive joints 145

4.4.1 Tensile tests 146

4.4.2 Lap-shear tests 149

4.4.3 Peel tests 151

4.4.4 Cleavage tests 156

4.4.5 Fatigue tests 157

4.4.6 Impact tests 158

4.4.7 Creep tests 160

4.4.8 Environmental tests 161

4.5 Standard test methods for sealant joints 163

4.5.1 Movement capability 164