Page 24 - Handbook of Adhesives and Sealants

P. 24

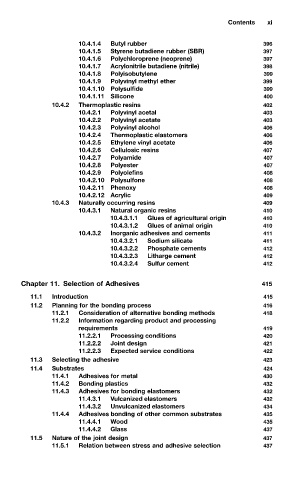

Contents xi

10.4.1.4 Butyl rubber 396

10.4.1.5 Styrene butadiene rubber (SBR) 397

10.4.1.6 Polychloroprene (neoprene) 397

10.4.1.7 Acrylonitrile butadiene (nitrile) 398

10.4.1.8 Polyisobutylene 399

10.4.1.9 Polyvinyl methyl ether 399

10.4.1.10 Polysulfide 399

10.4.1.11 Silicone 400

10.4.2 Thermoplastic resins 402

10.4.2.1 Polyvinyl acetal 403

10.4.2.2 Polyvinyl acetate 403

10.4.2.3 Polyvinyl alcohol 406

10.4.2.4 Thermoplastic elastomers 406

10.4.2.5 Ethylene vinyl acetate 406

10.4.2.6 Cellulosic resins 407

10.4.2.7 Polyamide 407

10.4.2.8 Polyester 407

10.4.2.9 Polyolefins 408

10.4.2.10 Polysulfone 408

10.4.2.11 Phenoxy 408

10.4.2.12 Acrylic 409

10.4.3 Naturally occurring resins 409

10.4.3.1 Natural organic resins 410

10.4.3.1.1 Glues of agricultural origin 410

10.4.3.1.2 Glues of animal origin 410

10.4.3.2 Inorganic adhesives and cements 411

10.4.3.2.1 Sodium silicate 411

10.4.3.2.2 Phosphate cements 412

10.4.3.2.3 Litharge cement 412

10.4.3.2.4 Sulfur cement 412

Chapter 11. Selection of Adhesives 415

11.1 Introduction 415

11.2 Planning for the bonding process 416

11.2.1 Consideration of alternative bonding methods 418

11.2.2 Information regarding product and processing

requirements 419

11.2.2.1 Processing conditions 420

11.2.2.2 Joint design 421

11.2.2.3 Expected service conditions 422

11.3 Selecting the adhesive 423

11.4 Substrates 424

11.4.1 Adhesives for metal 430

11.4.2 Bonding plastics 432

11.4.3 Adhesives for bonding elastomers 432

11.4.3.1 Vulcanized elastomers 432

11.4.3.2 Unvulcanized elastomers 434

11.4.4 Adhesives bonding of other common substrates 435

11.4.4.1 Wood 435

11.4.4.2 Glass 437

11.5 Nature of the joint design 437

11.5.1 Relation between stress and adhesive selection 437