Page 25 - Handbook of Adhesives and Sealants

P. 25

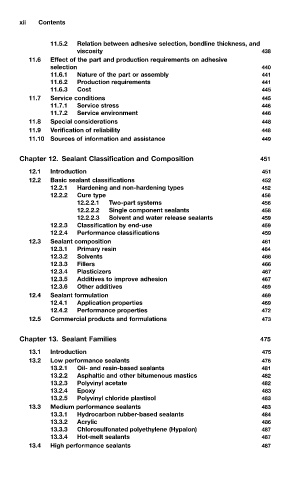

xii Contents

11.5.2 Relation between adhesive selection, bondline thickness, and

viscosity 438

11.6 Effect of the part and production requirements on adhesive

selection 440

11.6.1 Nature of the part or assembly 441

11.6.2 Production requirements 441

11.6.3 Cost 445

11.7 Service conditions 445

11.7.1 Service stress 446

11.7.2 Service environment 446

11.8 Special considerations 448

11.9 Verification of reliability 448

11.10 Sources of information and assistance 449

Chapter 12. Sealant Classification and Composition 451

12.1 Introduction 451

12.2 Basic sealant classifications 452

12.2.1 Hardening and non-hardening types 452

12.2.2 Cure type 456

12.2.2.1 Two-part systems 456

12.2.2.2 Single component sealants 458

12.2.2.3 Solvent and water release sealants 459

12.2.3 Classification by end-use 459

12.2.4 Performance classifications 459

12.3 Sealant composition 461

12.3.1 Primary resin 464

12.3.2 Solvents 466

12.3.3 Fillers 466

12.3.4 Plasticizers 467

12.3.5 Additives to improve adhesion 467

12.3.6 Other additives 469

12.4 Sealant formulation 469

12.4.1 Application properties 469

12.4.2 Performance properties 472

12.5 Commercial products and formulations 473

Chapter 13. Sealant Families 475

13.1 Introduction 475

13.2 Low performance sealants 476

13.2.1 Oil- and resin-based sealants 481

13.2.2 Asphaltic and other bitumenous mastics 482

13.2.3 Polyvinyl acetate 482

13.2.4 Epoxy 483

13.2.5 Polyvinyl chloride plastisol 483

13.3 Medium performance sealants 483

13.3.1 Hydrocarbon rubber-based sealants 484

13.3.2 Acrylic 486

13.3.3 Chlorosulfonated polyethylene (Hypalon) 487

13.3.4 Hot-melt sealants 487

13.4 High performance sealants 487