Page 23 - Handbook of Adhesives and Sealants

P. 23

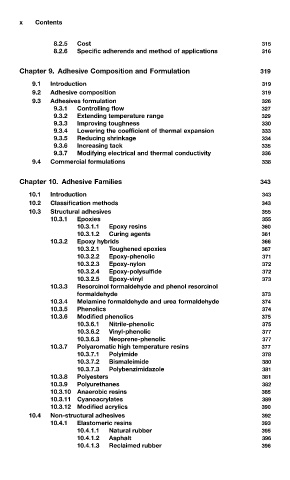

x Contents

8.2.5 Cost 315

8.2.6 Specific adherends and method of applications 316

Chapter 9. Adhesive Composition and Formulation 319

9.1 Introduction 319

9.2 Adhesive composition 319

9.3 Adhesives formulation 326

9.3.1 Controlling flow 327

9.3.2 Extending temperature range 329

9.3.3 Improving toughness 330

9.3.4 Lowering the coefficient of thermal expansion 333

9.3.5 Reducing shrinkage 334

9.3.6 Increasing tack 335

9.3.7 Modifying electrical and thermal conductivity 336

9.4 Commercial formulations 338

Chapter 10. Adhesive Families 343

10.1 Introduction 343

10.2 Classification methods 343

10.3 Structural adhesives 355

10.3.1 Epoxies 355

10.3.1.1 Epoxy resins 360

10.3.1.2 Curing agents 361

10.3.2 Epoxy hybrids 366

10.3.2.1 Toughened epoxies 367

10.3.2.2 Epoxy-phenolic 371

10.3.2.3 Epoxy-nylon 372

10.3.2.4 Epoxy-polysulfide 372

10.3.2.5 Epoxy-vinyl 373

10.3.3 Resorcinol formaldehyde and phenol resorcinol

formaldehyde 373

10.3.4 Melamine formaldehyde and urea formaldehyde 374

10.3.5 Phenolics 374

10.3.6 Modified phenolics 375

10.3.6.1 Nitrile-phenolic 375

10.3.6.2 Vinyl-phenolic 377

10.3.6.3 Neoprene-phenolic 377

10.3.7 Polyaromatic high temperature resins 377

10.3.7.1 Polyimide 378

10.3.7.2 Bismaleimide 380

10.3.7.3 Polybenzimidazole 381

10.3.8 Polyesters 381

10.3.9 Polyurethanes 382

10.3.10 Anaerobic resins 385

10.3.11 Cyanoacrylates 389

10.3.12 Modified acrylics 390

10.4 Non-structural adhesives 392

10.4.1 Elastomeric resins 393

10.4.1.1 Natural rubber 395

10.4.1.2 Asphalt 396

10.4.1.3 Reclaimed rubber 396