Page 27 - Handbook of Adhesives and Sealants

P. 27

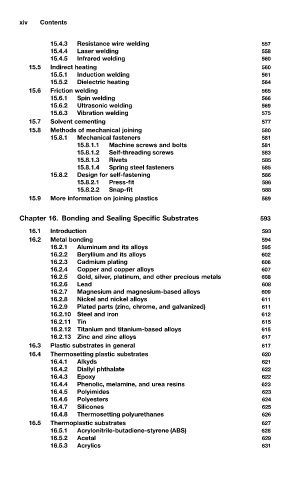

xiv Contents

15.4.3 Resistance wire welding 557

15.4.4 Laser welding 558

15.4.5 Infrared welding 560

15.5 Indirect heating 560

15.5.1 Induction welding 561

15.5.2 Dielectric heating 564

15.6 Friction welding 565

15.6.1 Spin welding 566

15.6.2 Ultrasonic welding 569

15.6.3 Vibration welding 575

15.7 Solvent cementing 577

15.8 Methods of mechanical joining 580

15.8.1 Mechanical fasteners 581

15.8.1.1 Machine screws and bolts 581

15.8.1.2 Self-threading screws 583

15.8.1.3 Rivets 585

15.8.1.4 Spring steel fasteners 585

15.8.2 Design for self-fastening 586

15.8.2.1 Press-fit 586

15.8.2.2 Snap-fit 588

15.9 More information on joining plastics 589

Chapter 16. Bonding and Sealing Specific Substrates 593

16.1 Introduction 593

16.2 Metal bonding 594

16.2.1 Aluminum and its alloys 595

16.2.2 Beryllium and its alloys 602

16.2.3 Cadmium plating 606

16.2.4 Copper and copper alloys 607

16.2.5 Gold, silver, platinum, and other precious metals 608

16.2.6 Lead 608

16.2.7 Magnesium and magnesium-based alloys 609

16.2.8 Nickel and nickel alloys 611

16.2.9 Plated parts (zinc, chrome, and galvanized) 611

16.2.10 Steel and iron 612

16.2.11 Tin 615

16.2.12 Titanium and titanium-based alloys 615

16.2.13 Zinc and zinc alloys 617

16.3 Plastic substrates in general 617

16.4 Thermosetting plastic substrates 620

16.4.1 Alkyds 621

16.4.2 Diallyl phthalate 622

16.4.3 Epoxy 622

16.4.4 Phenolic, melamine, and urea resins 623

16.4.5 Polyimides 623

16.4.6 Polyesters 624

16.4.7 Silicones 625

16.4.8 Thermosetting polyurethanes 626

16.5 Thermoplastic substrates 627

16.5.1 Acrylonitrile-butadiene-styrene (ABS) 628

16.5.2 Acetal 629

16.5.3 Acrylics 631