Page 28 - Handbook of Adhesives and Sealants

P. 28

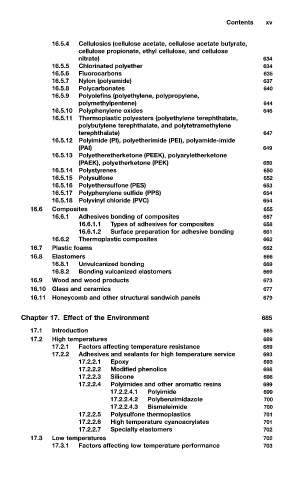

Contents xv

16.5.4 Cellulosics (cellulose acetate, cellulose acetate butyrate,

cellulose propionate, ethyl cellulose, and cellulose

nitrate) 634

16.5.5 Chlorinated polyether 634

16.5.6 Fluorocarbons 635

16.5.7 Nylon (polyamide) 637

16.5.8 Polycarbonates 640

16.5.9 Polyolefins (polyethylene, polypropylene,

polymethylpentene) 644

16.5.10 Polyphenylene oxides 646

16.5.11 Thermoplastic polyesters (polyethylene terephthalate,

polybutylene terephthalate, and polytetramethylene

terephthalate) 647

16.5.12 Polyimide (PI), polyetherimide (PEI), polyamide-imide

(PAI) 649

16.5.13 Polyetheretherketone (PEEK), polyaryletherketone

(PAEK), polyetherketone (PEK) 650

16.5.14 Polystyrenes 650

16.5.15 Polysulfone 652

16.5.16 Polyethersulfone (PES) 653

16.5.17 Polyphenylene sulfide (PPS) 654

16.5.18 Polyvinyl chloride (PVC) 654

16.6 Composites 655

16.6.1 Adhesives bonding of composites 657

16.6.1.1 Types of adhesives for composites 658

16.6.1.2 Surface preparation for adhesive bonding 661

16.6.2 Thermoplastic composites 662

16.7 Plastic foams 662

16.8 Elastomers 666

16.8.1 Unvulcanized bonding 669

16.8.2 Bonding vulcanized elastomers 669

16.9 Wood and wood products 673

16.10 Glass and ceramics 677

16.11 Honeycomb and other structural sandwich panels 679

Chapter 17. Effect of the Environment 685

17.1 Introduction 685

17.2 High temperatures 689

17.2.1 Factors affecting temperature resistance 689

17.2.2 Adhesives and sealants for high temperature service 693

17.2.2.1 Epoxy 693

17.2.2.2 Modified phenolics 698

17.2.2.3 Silicone 698

17.2.2.4 Polyimides and other aromatic resins 699

17.2.2.4.1 Polyimide 699

17.2.2.4.2 Polybenzimidazole 700

17.2.2.4.3 Bismaleimide 700

17.2.2.5 Polysulfone thermoplastics 701

17.2.2.6 High temperature cyanoacrylates 701

17.2.2.7 Specialty elastomers 702

17.3 Low temperatures 702

17.3.1 Factors affecting low temperature performance 703