Page 294 - Handbook of Battery Materials

P. 294

264 9 Metal Hydride Electrodes

300

250

200

Q, mAh 150

Zr 1-x Ti V Ni 1.1 Fe Mn .2

x .5

.2

100

x = 0.75

x = 0.5

50 x = 0.25

x = 0.0

0

0 50 100 150 200 250 300

Cycles

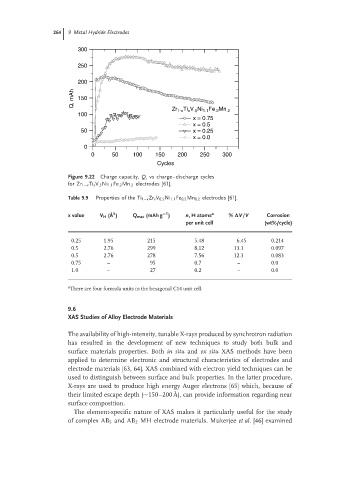

Figure 9.22 Charge capacity, Q, vs charge–discharge cycles

for Zr 1−x Ti x V .5 Ni 1.1 Fe .2 Mn .2 electrodes [61].

Table 9.9 Properties of the Ti 1−x Zr x V 0.5 Ni 1.1 Fe 0.2 Mn 0.2 electrodes [61].

3

−1

xvalue V H ( ˚ A ) Q max (mAh g ) n,H atoms a % ∆V/V Corrosion

per unit cell (wt%/cycle)

0.25 1.95 215 5.48 6.45 0.214

0.5 2.76 299 8.12 13.1 0.097

0.5 2.76 278 7.56 12.3 0.083

0.75 – 95 0.7 – 0.0

1.0 – 27 0.2 – 0.0

a

There are four formula units in the hexagonal C14 unit cell.

9.6

XAS Studies of Alloy Electrode Materials

The availability of high-intensity, tunable X-rays produced by synchrotron radiation

has resulted in the development of new techniques to study both bulk and

surface materials properties. Both in situ and ex situ XAS methods have been

applied to determine electronic and structural characteristics of electrodes and

electrode materials [63, 64]. XAS combined with electron yield techniques can be

used to distinguish between surface and bulk properties. In the latter procedure,

X-rays are used to produce high energy Auger electrons [65] which, because of

their limited escape depth (∼150–200 ˚ A), can provide information regarding near

surface composition.

The element-specific nature of XAS makes it particularly useful for the study

of complex AB 5 and AB 2 MH electrode materials. Mukerjee et al. [46] examined