Page 219 - Handbook of Civil Engineering Calculations, Second Edition

P. 219

2.4 REINFORCED AND PRESTRESSED CONCRETE ENGINEERING AND DESIGN

Design of Flexural Members by

Ultimate-Strength Method

In the ultimate-strength design of a reinforced-concrete structure, as in the plastic design

of a steel structure, the capacity of the structure is found by determining the load that will

cause failure and dividing this result by the prescribed load factor. The load at impending

failure is termed the ultimate load, and the maximum bending moment associated with

this load is called the ultimate moment.

Since the tensile strength of concrete is relatively small, it is generally disregarded en-

tirely in analyzing a beam. Consequently, the effective beam section is considered to

comprise the reinforcing steel and the concrete on the compression side of the neutral

axis, the concrete between these component areas serving merely as the ligature of the

member.

The following notational system is applied in ultimate-strength design: a depth of

compression block, in. (mm); c distance from extreme compression fiber to neutral

axis, in. (mm); capacity-reduction factor.

Where the subscript u is appended to a symbol, it signifies that the given quantity is

evaluated at ultimate load.

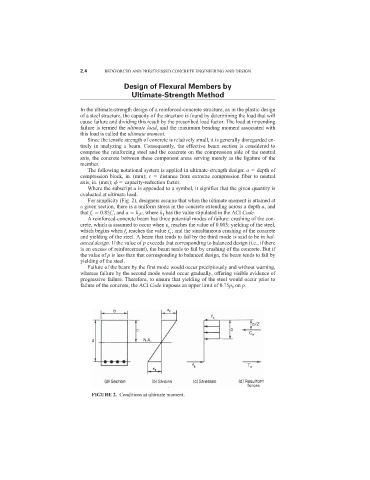

For simplicity (Fig. 2), designers assume that when the ultimate moment is attained at

a given section, there is a uniform stress in the concrete extending across a depth a, and

that f c 0.85f

c , and a k 1 c, where k 1 has the value stipulated in the ACI Code.

A reinforced-concrete beam has three potential modes of failure: crushing of the con-

crete, which is assumed to occur when

c reaches the value of 0.003; yielding of the steel,

which begins when f s reaches the value f y ; and the simultaneous crushing of the concrete

and yielding of the steel. A beam that tends to fail by the third mode is said to be in bal-

anced design. If the value of p exceeds that corresponding to balanced design (i.e., if there

is an excess of reinforcement), the beam tends to fail by crushing of the concrete. But if

the value of p is less than that corresponding to balanced design, the beam tends to fail by

yielding of the steel.

Failure of the beam by the first mode would occur precipitously and without warning,

whereas failure by the second mode would occur gradually, offering visible evidence of

progressive failure. Therefore, to ensure that yielding of the steel would occur prior to

failure of the concrete, the ACI Code imposes an upper limit of 0.75p b on p.

FIGURE 2. Conditions at ultimate moment.