Page 452 - Handbook of Energy Engineering Calculations

P. 452

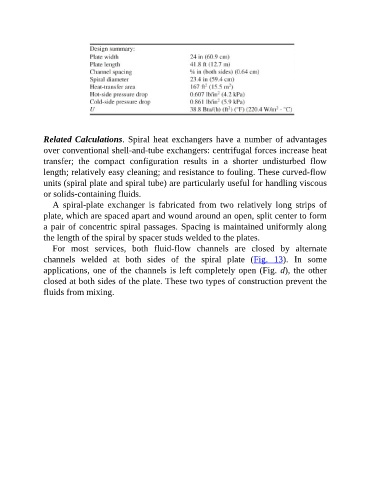

Related Calculations. Spiral heat exchangers have a number of advantages

over conventional shell-and-tube exchangers: centrifugal forces increase heat

transfer; the compact configuration results in a shorter undisturbed flow

length; relatively easy cleaning; and resistance to fouling. These curved-flow

units (spiral plate and spiral tube) are particularly useful for handling viscous

or solids-containing fluids.

A spiral-plate exchanger is fabricated from two relatively long strips of

plate, which are spaced apart and wound around an open, split center to form

a pair of concentric spiral passages. Spacing is maintained uniformly along

the length of the spiral by spacer studs welded to the plates.

For most services, both fluid-flow channels are closed by alternate

channels welded at both sides of the spiral plate (Fig. 13). In some

applications, one of the channels is left completely open (Fig. d), the other

closed at both sides of the plate. These two types of construction prevent the

fluids from mixing.