Page 161 - Handbook of Materials Failure Analysis

P. 161

7 Conclusion 157

1200

y = 3.9967x

Sleeper/ballast contact pressure (kPa) 800

2

R = 0.9998

1000

600

400

200

0

0 50 100 150 200 250 300

Rail seat load (kN)

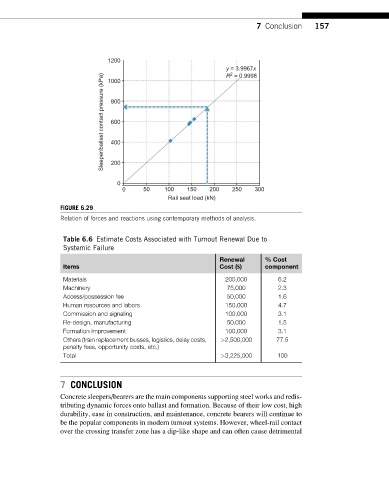

FIGURE 6.29

Relation of forces and reactions using contemporary methods of analysis.

Table 6.6 Estimate Costs Associated with Turnout Renewal Due to

Systemic Failure

Renewal % Cost

Items Cost ($) component

Materials 200,000 6.2

Machinery 75,000 2.3

Access/possession fee 50,000 1.6

Human resources and labors 150,000 4.7

Commission and signaling 100,000 3.1

Re-design, manufacturing 50,000 1.5

Formation improvement 100,000 3.1

Others (train replacement busses, logistics, delay costs, >2,500,000 77.5

penalty fees, opportunity costs, etc.)

Total >3,225,000 100

7 CONCLUSION

Concrete sleepers/bearers are the main components supporting steel works and redis-

tributing dynamic forces onto ballast and formation. Because of their low cost, high

durability, ease in construction, and maintenance, concrete bearers will continue to

be the popular components in modern turnout systems. However, wheel-rail contact

over the crossing transfer zone has a dip-like shape and can often cause detrimental