Page 365 - Handbook of Materials Failure Analysis

P. 365

2 Fatigue Modeling of Welded Structures by Local Approaches 363

fracture mechanics-based models, often provides enough flexibility to be applicable

to different specimens and structures. Therefore, these models are widely employed

in industry, including the automobile industry [9]. However, some weak points are

also associated with this approach. A serious shortcoming is that the notch effect at

the spot-weld edge is ignored [9].

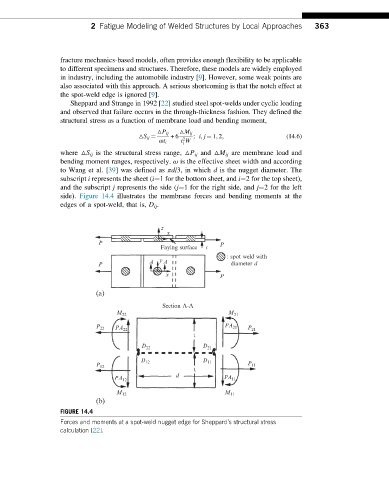

Sheppard and Strange in 1992 [22] studied steel spot-welds under cyclic loading

and observed that failure occurs in the through-thickness fashion. They defined the

structural stress as a function of membrane load and bending moment,

△P ij △M ij

△S ij ¼ +6 2 ; i, j ¼ 1, 2; (14.6)

ωt i t W

i

where △S ij is the structural stress range, △P ij and △M ij are membrane load and

bending moment ranges, respectively. ω is the effective sheet width and according

to Wang et al. [39] was defined as πd/3, in which d is the nugget diameter. The

subscript i represents the sheet (i¼1 for the bottom sheet, and i¼2 for the top sheet),

and the subscript j represents the side (j¼1 for the right side, and j¼2 for the left

side). Figure 14.4 illustrates the membrane forces and bending moments at the

edges of a spot-weld, that is, D ij .

z

x

P P

Faying surface t

: spot weld with

A y A

P diameter d

x P

(a)

Section A-A

M 22 M 21

P 22 PA 22 PA 21 P 21

t

D 22 D 21

D 12 D 11

P 12 P 11

t

PA 12 d PA 11

M 12 M 11

(b)

FIGURE 14.4

Forces and moments at a spot-weld nugget edge for Sheppard’s structural stress

calculation [22].