Page 369 - Handbook of Materials Failure Analysis

P. 369

3 Case Study: Fatigue Life Assessment of an Automotive Demo-Structure 367

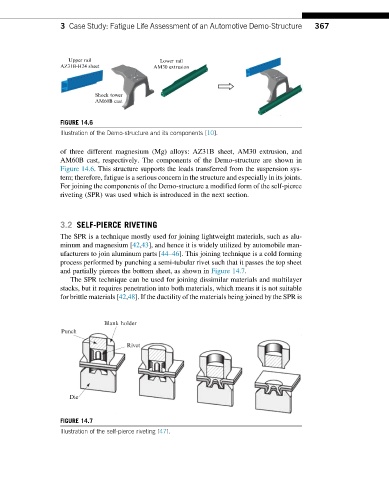

Upper rail Lower rail

AZ31B-H24 sheet AM30 extrusion

Shock tower

AM60B cast

FIGURE 14.6

Illustration of the Demo-structure and its components [10].

of three different magnesium (Mg) alloys: AZ31B sheet, AM30 extrusion, and

AM60B cast, respectively. The components of the Demo-structure are shown in

Figure 14.6. This structure supports the loads transferred from the suspension sys-

tem; therefore, fatigue is a serious concern in the structure and especially in its joints.

For joining the components of the Demo-structure a modified form of the self-pierce

riveting (SPR) was used which is introduced in the next section.

3.2 SELF-PIERCE RIVETING

The SPR is a technique mostly used for joining lightweight materials, such as alu-

minum and magnesium [42,43], and hence it is widely utilized by automobile man-

ufacturers to join aluminum parts [44–46]. This joining technique is a cold forming

process performed by punching a semi-tubular rivet such that it passes the top sheet

and partially pierces the bottom sheet, as shown in Figure 14.7.

The SPR technique can be used for joining dissimilar materials and multilayer

stacks, but it requires penetration into both materials, which means it is not suitable

for brittle materials [42,48]. If the ductility of the materials being joined by the SPR is

Blank holder

Punch

Rivet

Die

FIGURE 14.7

Illustration of the self-pierce riveting [47].