Page 392 - Handbook of Materials Failure Analysis

P. 392

390 CHAPTER 15 Welding-associated failures in power boilers

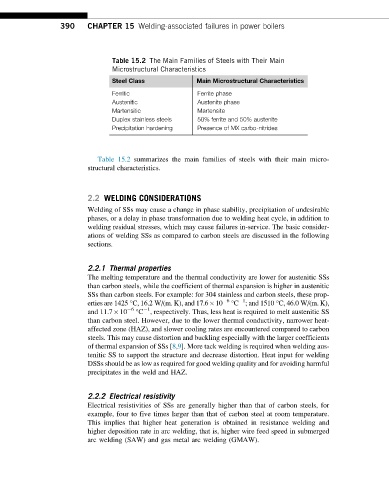

Table 15.2 The Main Families of Steels with Their Main

Microstructural Characteristics

Steel Class Main Microstructural Characteristics

Ferritic Ferrite phase

Austenitic Austenite phase

Martensitic Martensite

Duplex stainless steels 50% ferrite and 50% austenite

Precipitation hardening Presence of MX carbo-nitrides

Table 15.2 summarizes the main families of steels with their main micro-

structural characteristics.

2.2 WELDING CONSIDERATIONS

Welding of SSs may cause a change in phase stability, precipitation of undesirable

phases, or a delay in phase transformation due to welding heat cycle, in addition to

welding residual stresses, which may cause failures in-service. The basic consider-

ations of welding SSs as compared to carbon steels are discussed in the following

sections.

2.2.1 Thermal properties

The melting temperature and the thermal conductivity are lower for austenitic SSs

than carbon steels, while the coefficient of thermal expansion is higher in austenitic

SSs than carbon steels. For example: for 304 stainless and carbon steels, these prop-

1

erties are 1425 °C, 16.2 W/(m. K), and 17.6 10 6 °C ; and 1510 °C, 46.0 W/(m. K),

1

and 11.7 10 6 °C , respectively. Thus, less heat is required to melt austenitic SS

than carbon steel. However, due to the lower thermal conductivity, narrower heat-

affected zone (HAZ), and slower cooling rates are encountered compared to carbon

steels. This may cause distortion and buckling especially with the larger coefficients

of thermal expansion of SSs [8,9]. More tack welding is required when welding aus-

tenitic SS to support the structure and decrease distortion. Heat input for welding

DSSs should be as low as required for good welding quality and for avoiding harmful

precipitates in the weld and HAZ.

2.2.2 Electrical resistivity

Electrical resistivities of SSs are generally higher than that of carbon steels, for

example, four to five times larger than that of carbon steel at room temperature.

This implies that higher heat generation is obtained in resistance welding and

higher deposition rate in arc welding, that is, higher wire feed speed in submerged

arc welding (SAW) and gas metal arc welding (GMAW).