Page 41 - Handbook of Materials Failure Analysis

P. 41

34 CHAPTER 2 Failure analysis in chemical industries

Isometric drawing

of drainage caustic line

Over head

road crossing

N E Spent caustic 23 M 1.M raise of

storage tank pipe line

W 930 TK 5

4 Dia

2 M 58.M

10.7 M 1.75

Defective potron

5.3

40.0 M

2.3 M 1 M

85.M

40.0 M

4 Dia Intermittent flow

8-10 m 3 /hr

4 Dla

To tank

from area 500

RCC

Ground

69.0 M support support

4 Dla 1.5 Dla Continuous flow

1.0~2.0 m 3 /hr GROUND

from area 400

Blind

1.0 M

4 Dla

No flow from

area 300

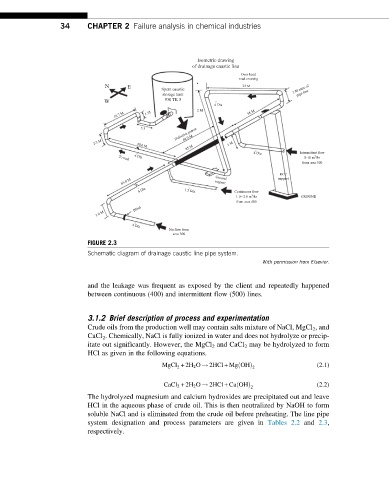

FIGURE 2.3

Schematic diagram of drainage caustic line pipe system.

With permission from Elsevier.

and the leakage was frequent as exposed by the client and repeatedly happened

between continuous (400) and intermittent flow (500) lines.

3.1.2 Brief description of process and experimentation

Crude oils from the production well may contain salts mixture of NaCl, MgCl 2 , and

CaCl 2 . Chemically, NaCl is fully ionized in water and does not hydrolyze or precip-

itate out significantly. However, the MgCl 2 and CaCl 2 may be hydrolyzed to form

HCl as given in the following equations.

ð

MgCl +2H 2 O ! 2HCl + Mg OHÞ (2.1)

2 2

CaCl 2 +2H 2 O ! 2HCl + Ca OHð Þ 2 (2.2)

The hydrolyzed magnesium and calcium hydroxides are precipitated out and leave

HCl in the aqueous phase of crude oil. This is then neutralized by NaOH to form

soluble NaCl and is eliminated from the crude oil before preheating. The line pipe

system designation and process parameters are given in Tables 2.2 and 2.3,

respectively.