Page 480 - Handbook of Materials Failure Analysis

P. 480

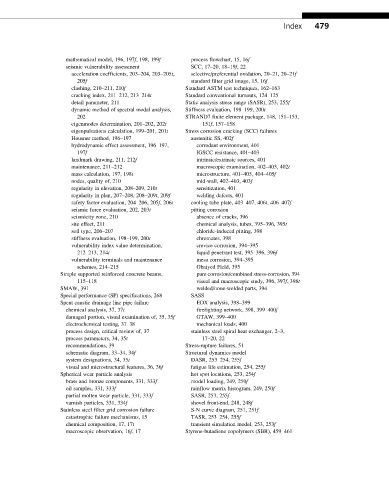

Index 479

mathematical model, 196, 197f, 198, 199f process flowchart, 15, 16f

seismic vulnerability assessment SCC, 17–20, 18–19f,22

acceleration coefficients, 203–204, 203–205t, selective/preferential oxidation, 20–21, 20–21f

205f standard filter grid image, 15, 16f

clashing, 210–211, 210f Standard ASTM test techniques, 162–163

cracking index, 211–212, 213–214t Standard conventional turnouts, 124–125

detail parameter, 211 Static analysis stress range (SASR), 253, 255f

dynamic method of spectral modal analysis, Stiffness evaluation, 198–199, 200t

202 STRAND7 finite element package, 148, 151–153,

eigenmodes determination, 201–202, 202t 151f, 157–158

eigenpulsations calculation, 199–201, 201t Stress corrosion cracking (SCC) failures

Housner method, 196–197 austenitic SS, 402f

hydrodynamic effect assessment, 196–197, corrodant environment, 401

197f IGSCC resistance, 401–403

landmark drawing, 211, 212f intrinsic/extrinsic sources, 401

maintenance, 211–212 macroscopic examination, 402–403, 402t

mass calculation, 197, 198t microstructure, 401–403, 404–405f

nodes, quality of, 210 mid-wall, 402–403, 403f

regularity in elevation, 208–209, 210t sensitization, 401

regularity in plan, 207–208, 208–209t, 209f welding defects, 401

safety factor evaluation, 204–206, 205f, 206t cooling tube plate, 403–407, 406t, 406–407f

seismic force evaluation, 202, 203t pitting corrosion

seismicity zone, 210 absence of cracks, 396

site effect, 211 chemical analysis, tubes, 395–396, 395t

soil type, 206–207 chloride-induced pitting, 398

stiffness evaluation, 198–199, 200t chromates, 398

vulnerability index value determination, crevice corrosion, 394–395

212–213, 214t liquid penetrant test, 395–396, 396f

vulnerability terminals and maintenance mesa corrosion, 394–395

schemes, 214–215 Obaiyed Field, 395

Simple supported reinforced concrete beams, pure corrosion/combined stress-corrosion, 394

115–118 visual and macroscopic study, 396, 397f, 398t

SMAW, 391 welded/none-welded parts, 394

Special performance (SP) specifications, 268 SASS

Spent caustic drainage line pipe failure EDX analysis, 398–399

chemical analysis, 37, 37t firefighting network, 398, 399–400f

damaged portion, visual examination of, 35, 35f GTAW, 399–400

electrochemical testing, 37–38 mechanical loads, 400

process design, critical review of, 37 stainless steel spiral heat exchanger, 2–3,

process parameters, 34, 35t 17–20, 22

recommendations, 39 Stress-rupture failures, 51

schematic diagram, 33–34, 34f Structural dynamics model

system designations, 34, 35t DASR, 253–254, 255f

visual and microstructural features, 36, 36f fatigue life estimation, 254, 255f

Spherical wear particle analysis hot spot locations, 253, 254f

brass and bronze components, 331, 333f model loading, 249, 250f

oil samples, 331, 333f rainflow matrix histogram, 249, 250f

partial molten wear particle, 331, 333f SASR, 253, 255f

varnish particles, 331, 334f shovel front-end, 248, 248f

Stainless steel filter grid corrosion failure S-N curve diagram, 251, 251f

catastrophic failure mechanisms, 15 TASR, 253–254, 255f

chemical composition, 17, 17t transient simulation model, 253, 253f

macroscopic observation, 16f,17 Styrene-butadiene copolymers (SBR), 459–461