Page 52 - Handbook of Materials Failure Analysis

P. 52

3 Case Studies 45

CT Feed water

20.00 µ

10.00 µ

i (A/cm 2 ) −10.00 µ

0.000

−20.00 µ

−30.00 µ

0.000 s 50.00 s 100.0 s 150.0 s 200.0 s

(a) T (s)

CT Bleed water

50.00 m

0.000

i (A/cm 2 )

−50.00 m

−10.00 m

0.000 s 50.00 s 100.0 s 150.0 s 200.0 s

(b) T (s)

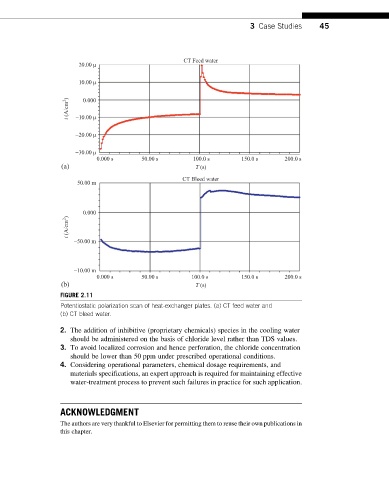

FIGURE 2.11

Potentiostatic polarization scan of heat-exchanger plates. (a) CT feed water and

(b) CT bleed water.

2. The addition of inhibitive (proprietary chemicals) species in the cooling water

should be administered on the basis of chloride level rather than TDS values.

3. To avoid localized corrosion and hence perforation, the chloride concentration

should be lower than 50 ppm under prescribed operational conditions.

4. Considering operational parameters, chemical dosage requirements, and

materials specifications, an expert approach is required for maintaining effective

water-treatment process to prevent such failures in practice for such application.

ACKNOWLEDGMENT

The authors are very thankful to Elsevier for permitting them to reuse their own publications in

this chapter.