Page 100 - Handbook of Plastics Technologies

P. 100

THERMOPLASTICS

2.40 CHAPTER 2

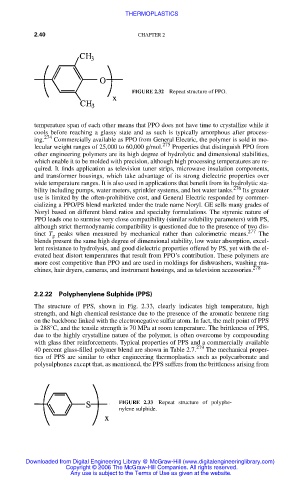

FIGURE 2.32 Repeat structure of PPO.

temperature span of each other means that PPO does not have time to crystallize while it

cools before reaching a glassy state and as such is typically amorphous after process-

274

ing. Commercially available as PPO from General Electric, the polymer is sold in mo-

275

lecular weight ranges of 25,000 to 60,000 g/mol. Properties that distinguish PPO from

other engineering polymers are its high degree of hydrolytic and dimensional stabilities,

which enable it to be molded with precision, although high processing temperatures are re-

quired. It finds application as television tuner strips, microwave insulation components,

and transformer housings, which take advantage of its strong dielectric properties over

wide temperature ranges. It is also used in applications that benefit from its hydrolytic sta-

276

bility including pumps, water meters, sprinkler systems, and hot water tanks. Its greater

use is limited by the often-prohibitive cost, and General Electric responded by commer-

cializing a PPO/PS blend marketed under the trade name Noryl. GE sells many grades of

Noryl based on different blend ratios and specialty formulations. The styrenic nature of

PPO leads one to surmise very close compatibility (similar solubility parameters) with PS,

although strict thermodynamic compatibility is questioned due to the presence of two dis-

277

tinct T peaks when measured by mechanical rather than calorimetric means. The

g

blends present the same high degree of dimensional stability, low water absorption, excel-

lent resistance to hydrolysis, and good dielectric properties offered by PS, yet with the el-

evated heat distort temperatures that result from PPO’s contribution. These polymers are

more cost competitive than PPO and are used in moldings for dishwashers, washing ma-

278

chines, hair dryers, cameras, and instrument housings, and as television accessories.

2.2.22 Polyphenylene Sulphide (PPS)

The structure of PPS, shown in Fig. 2.33, clearly indicates high temperature, high

strength, and high chemical resistance due to the presence of the aromatic benzene ring

on the backbone linked with the electronegative sulfur atom. In fact, the melt point of PPS

is 288°C, and the tensile strength is 70 MPa at room temperature. The brittleness of PPS,

due to the highly crystalline nature of the polymer, is often overcome by compounding

with glass fiber reinforcements. Typical properties of PPS and a commercially available

279

40 percent glass-filled polymer blend are shown in Table 2.7. The mechanical proper-

ties of PPS are similar to other engineering thermoplastics such as polycarbonate and

polysulphones except that, as mentioned, the PPS suffers from the brittleness arising from

FIGURE 2.33 Repeat structure of polyphe-

nylene sulphide.

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2006 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.