Page 95 - Handbook of Plastics Technologies

P. 95

THERMOPLASTICS

THERMOPLASTICS 2.35

2.2.17 Polyimide (PI)

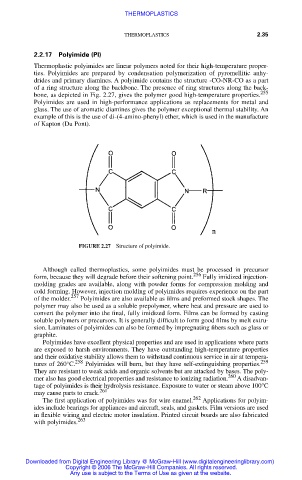

Thermoplastic polyimides are linear polymers noted for their high-temperature proper-

ties. Polyimides are prepared by condensation polymerization of pyromellitic anhy-

drides and primary diamines. A polyimide contains the structure -CO-NR-CO as a part

of a ring structure along the backbone. The presence of ring structures along the back-

bone, as depicted in Fig. 2.27, gives the polymer good high-temperature properties. 255

Polyimides are used in high-performance applications as replacements for metal and

glass. The use of aromatic diamines gives the polymer exceptional thermal stability. An

example of this is the use of di-(4-amino-phenyl) ether, which is used in the manufacture

of Kapton (Du Pont).

FIGURE 2.27 Structure of polyimide.

Although called thermoplastics, some polyimides must be processed in precursor

form, because they will degrade before their softening point. 256 Fully imidized injection-

molding grades are available, along with powder forms for compression molding and

cold forming. However, injection molding of polyimides requires experience on the part

of the molder. 257 Polyimides are also available as films and preformed stock shapes. The

polymer may also be used as a soluble prepolymer, where heat and pressure are used to

convert the polymer into the final, fully imidized form. Films can be formed by casting

soluble polymers or precursors. It is generally difficult to form good films by melt extru-

sion. Laminates of polyimides can also be formed by impregnating fibers such as glass or

graphite.

Polyimides have excellent physical properties and are used in applications where parts

are exposed to harsh environments. They have outstanding high-temperature properties

and their oxidative stability allows them to withstand continuous service in air at tempera-

tures of 260°C. 258 Polyimides will burn, but they have self-extinguishing properties. 259

They are resistant to weak acids and organic solvents but are attacked by bases. The poly-

mer also has good electrical properties and resistance to ionizing radiation. 260 A disadvan-

tage of polyimides is their hydrolysis resistance. Exposure to water or steam above 100°C

may cause parts to crack. 261

262

The first application of polyimides was for wire enamel. Applications for polyim-

ides include bearings for appliances and aircraft, seals, and gaskets. Film versions are used

in flexible wiring and electric motor insulation. Printed circuit boards are also fabricated

263

with polyimides.

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2006 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.