Page 93 - Handbook of Plastics Technologies

P. 93

THERMOPLASTICS

THERMOPLASTICS 2.33

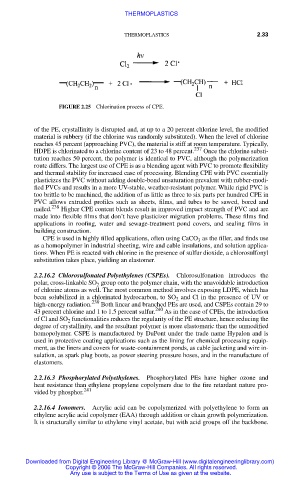

FIGURE 2.25 Chlorination process of CPE.

of the PE, crystallinity is disrupted and, at up to a 20 percent chlorine level, the modified

material is rubbery (if the chlorine was randomly substituted). When the level of chlorine

reaches 45 percent (approaching PVC), the material is stiff at room temperature. Typically,

237

HDPE is chlorinated to a chlorine content of 23 to 48 percent. Once the chlorine substi-

tution reaches 50 percent, the polymer is identical to PVC, although the polymerization

route differs. The largest use of CPE is as a blending agent with PVC to promote flexibility

and thermal stability for increased ease of processing. Blending CPE with PVC essentially

plasticizes the PVC without adding double-bond unsaturation prevalent with rubber-modi-

fied PVCs and results in a more UV-stable, weather-resistant polymer. While rigid PVC is

too brittle to be machined, the addition of as little as three to six parts per hundred CPE in

PVC allows extruded profiles such as sheets, films, and tubes to be sawed, bored and

238

nailed. Higher CPE content blends result in improved impact strength of PVC and are

made into flexible films that don’t have plasticizer migration problems. These films find

applications in roofing, water and sewage-treatment pond covers, and sealing films in

building construction.

CPE is used in highly filled applications, often using CaCO as the filler, and finds use

3

as a homopolymer in industrial sheeting, wire and cable insulations, and solution applica-

tions. When PE is reacted with chlorine in the presence of sulfur dioxide, a chlorosulfonyl

substitution takes place, yielding an elastomer.

2.2.16.2 Chlorosulfonated Polyethylenes (CSPEs). Chlorosulfonation introduces the

polar, cross-linkable SO group onto the polymer chain, with the unavoidable introduction

2

of chlorine atoms as well. The most common method involves exposing LDPE, which has

been solubilized in a chlorinated hydrocarbon, to SO and Cl in the presence of UV or

2

high-energy radiation. 239 Both linear and branched PEs are used, and CSPEs contain 29 to

43 percent chlorine and 1 to 1.5 percent sulfur. 240 As in the case of CPEs, the introduction

of Cl and SO functionalities reduces the regularity of the PE structure, hence reducing the

2

degree of crystallinity, and the resultant polymer is more elastomeric than the unmodified

homopolymer. CSPE is manufactured by DuPont under the trade name Hypalon and is

used in protective coating applications such as the lining for chemical processing equip-

ment, as the liners and covers for waste-containment ponds, as cable jacketing and wire in-

sulation, as spark plug boots, as power steering pressure hoses, and in the manufacture of

elastomers.

2.2.16.3 Phosphorylated Polyethylenes. Phosphorylated PEs have higher ozone and

heat resistance than ethylene propylene copolymers due to the fire retardant nature pro-

vided by phosphor. 241

2.2.16.4 Ionomers. Acrylic acid can be copolymerized with polyethylene to form an

ethylene acrylic acid copolymer (EAA) through addition or chain growth polymerization.

It is structurally similar to ethylene vinyl acetate, but with acid groups off the backbone.

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2006 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.