Page 82 - Handbook of Properties of Textile and Technical Fibres

P. 82

Properties of wool 63

R O R O R O R O

H H H H

N N N N

HN N N N N

H H H H

HN O CH O CH 2 O CH 2 O CH 2

O H 3 C CH 3 H 2 C O OC

Hydrophobic bond H

CH 2 Hydrogen NH

CH 2

bond Isopeptide

Intermolecular S H 2 C Ionic O H 2 C cross-link

disulfide cross-link bond NH 2

S NH 3 C CH 2

COO H 2 C H 2 C

CH 2

HN O CH 2 O H 2 C O CH 2 O CH 2

H H H H H

N N N N N

N N N N

O H H H H

R O H 2 C O CH 2 O R O

S S

Intramolecular

disulfide cross-link

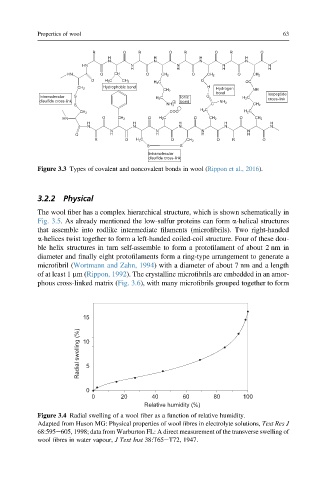

Figure 3.3 Types of covalent and noncovalent bonds in wool (Rippon et al., 2016).

3.2.2 Physical

The wool fiber has a complex hierarchical structure, which is shown schematically in

Fig. 3.5. As already mentioned the low-sulfur proteins can form a-helical structures

that assemble into rodlike intermediate filaments (microfibrils). Two right-handed

a-helices twist together to form a left-handed coiled-coil structure. Four of these dou-

ble helix structures in turn self-assemble to form a protofilament of about 2 nm in

diameter and finally eight protofilaments form a ring-type arrangement to generate a

microfibril (Wortmann and Zahn, 1994) with a diameter of about 7 nm and a length

of at least 1 mm(Rippon, 1992). The crystalline microfibrils are embedded in an amor-

phous cross-linked matrix (Fig. 3.6), with many microfibrils grouped together to form

15

Radial swelling (%) 10 5

0

0 20 40 60 80 100

Relative humidity (%)

Figure 3.4 Radial swelling of a wool fiber as a function of relative humidity.

Adapted from Huson MG: Physical properties of wool fibres in electrolyte solutions, Text Res J

68:595e605, 1998; data from Warburton FL: A direct measurement of the transverse swelling of

wool fibres in water vapour, J Text Inst 38:T65eT72, 1947.