Page 121 - Handbook of Structural Steel Connection Design and Details

P. 121

Design of Connections for Axial, Moment, and Shear Forces

106 Chapter Two

b. Bearing: This has been considered with the angles, above.

c. Prying action: Prying action explicitly refers to the extra tensile

force in bolts that connect flexible plates or flanges subjected to

loads normal to the flanges. For this reason, prying action involves

not only the bolts but the flange thickness, bolt pitch and gage, and

in general, the geometry of the entire connection.

The AISC LRFD Manual presents a method to calculate the

effects of prying. This method was originally developed by Struik

(1969) and presented in the book (Kulak et al., 1987). The form used

in the AISC LRFD Manual was developed by Thornton (1985), for

ease of calculation and to provide optimum results, that is, maxi-

mum capacity for a given connection (analysis) and minimum

required thickness for a given load (design). Thornton (1992, 1997)

has shown that this method gives a very conservative estimate of

ultimate load and shows that very close estimates of ultimate load

can be obtained by using the flange ultimate strength, F , in place

u

of yield strength, F , in the prying action formulas. More recently,

y

Swanson (2002) has confirmed Thornton’s (1992, 1997) results with

modern materials. For this reason, the AISC Manual now uses F

u

in place of F in the prying action formulas. Note that the resistance

y

factor, , used with the F is 0.90, because the flange failure mode

u

is yielding with strain hardening rather than fracture.

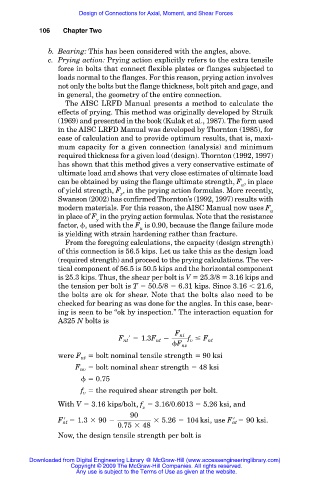

From the foregoing calculations, the capacity (design strength)

of this connection is 56.5 kips. Let us take this as the design load

(required strength) and proceed to the prying calculations. The ver-

tical component of 56.5 is 50.5 kips and the horizontal component

is 25.3 kips. Thus, the shear per bolt is V 25.3/8 3.16 kips and

the tension per bolt is T 50.5/8 6.31 kips. Since 3.16 21.6,

the bolts are ok for shear. Note that the bolts also need to be

checked for bearing as was done for the angles. In this case, bear-

ing is seen to be “ok by inspection.” The interaction equation for

A325 N bolts is

F nt

F r 5 1.3F nt 2 f # F nt

nt

v

F nv

were F nt bolt nominal tensile strength 90 ksi

F nv bolt nominal shear strength 48 ksi

0.75

f v the required shear strength per bolt.

With V 3.16 kips/bolt, f 3.16/0.6013 5.26 ksi, and

v

90

5

F 5 1.3 3 90 2 3 5.26 5 104 ksi , use F nt 90 ksi.

nt

0.75 3 48

Now, the design tensile strength per bolt is

Downloaded from Digital Engineering Library @ McGraw-Hill (www.accessengineeringlibrary.com)

Copyright © 2009 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.